News

Martyna’s Journey to Leadership

July 12, 2024

Martyna Adamska, an Engineering Manager at TWD, powered through the typical self-doubt of a recent graduate in her early career at TWD. Inspired by her colleagues, feeling trusted by her leads and setting high goals for herself, she grew through a variety of roles that built her confidence and skillset. Now, she is happy to lead impactful projects, support junior development and call the Netherlands her forever home.

TWD assists Arctic Reflections with method engineering to thicken Arctic Sea ice

July 1, 2024

TWD is collaborating with Arctic Reflections, an innovative environmental startup dedicated to reversing the rapid decline of Arctic Sea ice. TWD’s contributions include structuring the developments of Arctic Reflections with project management tools, providing creative and pragmatic engineering assistance for their technical, and logistical challenges and providing practical assistance in preparation of the Arctic tests.

TWD Participates in Dutch Offshore Wind Trade Mission to South-Korea

June 25, 2024

TWD participated in the Dutch Offshore Wind Trade Mission to South Korea. This event aimed to strengthen ties between the Dutch and Korean offshore wind sectors. The mission featured a Netherlands-Korea Offshore Wind Seminar, including a series of presentations and networking sessions. Commercial Manager Simon Lembrechts showcased TWD’s expertise in the installation and transportation of foundations.

Pros and Cons of Modularization: A Rising Trend in Construction

May 2, 2024

As the world moves from traditional stick-built methods to modular construction, this article highlights the benefits and challenges of choosing modularization over stick-built construction. Our latest infographic offers a detailed, step-by-step guide on tackling the challenges associated with module transportation, from selecting cranes and vessels to on-site inspection and mobilization.

TWD Innovation: smart and multi-functional Modular Tugger Frame

May 1, 2024

TWD is excited to introduce the Modular Tugger Frame (MTF), which addresses the challenge arising from the diversity in designs of secondary steel components across different wind farms. This innovative solution improves secondary steel installation by leveraging its simple yet smart functionalities. It was designed to assist in installing various secondary steel components with a cohesive and efficient installation workflow.

TWD Installation Equipment Designs ready to assist in Hai Long OWF Installation Hai Long Template

April 17, 2024

Last week, the Hai Long Offshore Wind Project announced the official launch of offshore construction. TWD was awarded the tailored design of the pin pile installation equipment by CSBC-DEME Wind Engineering (CDWE). Our tailored designs will play a key role in the installation process of Hai Long, with a capacity exceeding 1 GW, with the Green Jade vessel.

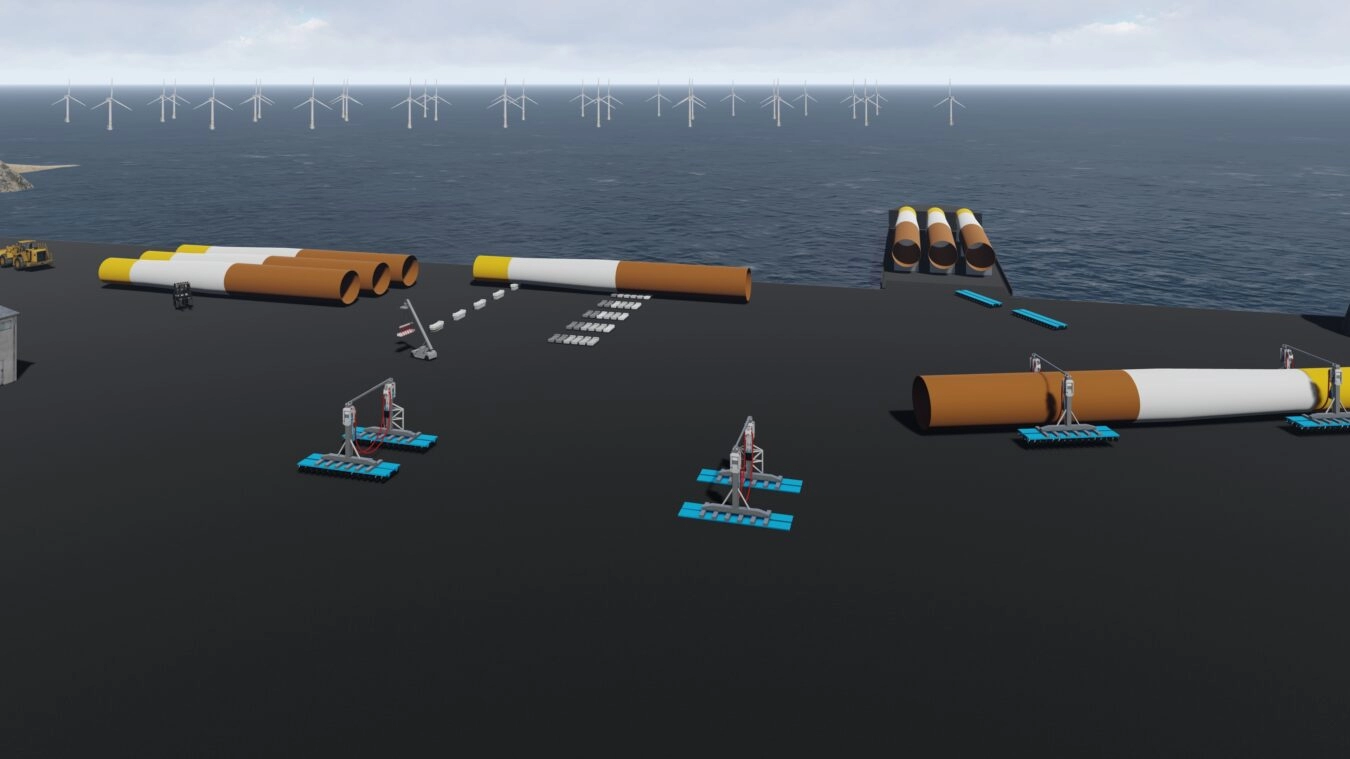

Port Yard Pile Storage

April 10, 2024

We are delighted to introduce our latest novel solution for Yard Pile Storage. This innovative method uses heavy-duty storage bags engineered to handle significant loads of the stored monopiles.

TWD’s Innovative Heavy Lift Spreader Beam App

March 21, 2024

Suited for lifts of 100 to 1000 tonnes and based on your lift specific inputs, the Heavy Lift Spreader Beam app generates a custom spreader design and checks the stability of your lift.

New whitepaper: Lifting the Future of Monopile Installation

March 7, 2024

The rapid growth of the global wind energy sector, driven by ambitious government targets, is leading to expansion into new offshore locations with deeper water and weaker ground conditions. This, together with increasing turbine sizes and capacities, requires innovative solutions for installing larger and heavier monopiles. TWD has published a white paper on the installation of ‘future monopiles’, providing insight into the challenges and innovative solutions.

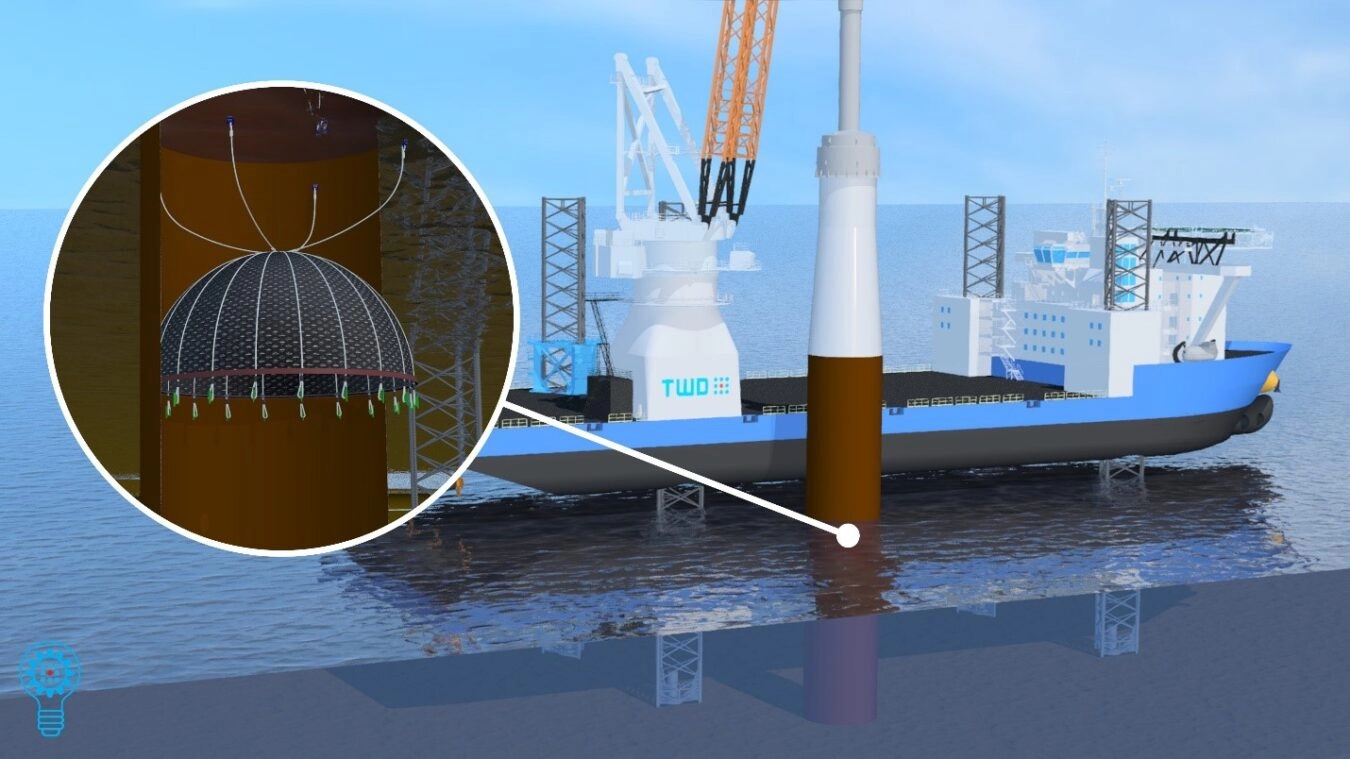

Pile Run Parachute (PRP)

February 28, 2024

Meet one of TWD’s innovative designs, the Pile Run Parachute (PRP). It combines materials already commonly used in offshore applications, such as steel wires and geosynthetic materials, to create an inner damper. This reduces the maximum velocity as well as the depth at which the pile run terminates.

Example Projects

Jacket Flange Lifting Tool for TPCII

Read more