Drive & Control Engineering

TWD has established solid expertise in Drive and Control (D&C) to optimize the effectiveness of your mechanical design and project operational sequence. We can advise you on the technical and functional specifications that are crucial to smart mechanical designs.

Thanks to our multidisciplinary in-house talents, we can combine Drive and Control with mechanical, structural, marine, and dynamics expertise to oversee all critical interfaces across your project. Because we consider the specifications of your Drive and Control systems at an early project stage, you can save precious time for long-lead project items. Some of the common Drive and Control areas we specialize in include hydraulic motors and cylinders and their power requirements, sensors, redundancy, and automation.

Our Expertise

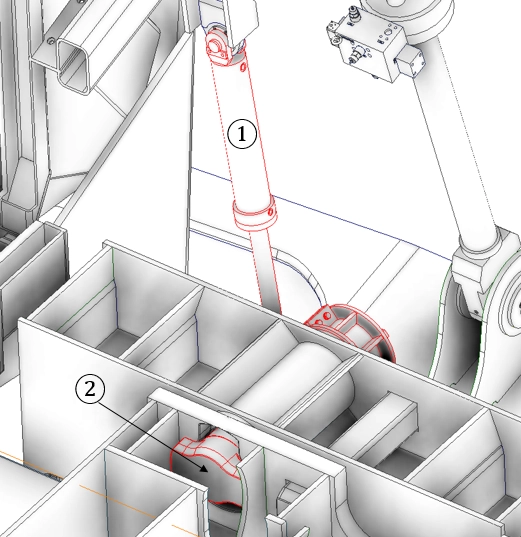

A well-selected actuator is an integral part of a functional design. At TWD, we have extensive experience in determining the best actuators for your equipment. Carefully attending to all the specifics of your design, our engineers can help you select a wide range of actuators, such as hydraulic motors/ cylinders, winches, or rack and pinion systems. By finding the perfect actuator match for your machine, we can guarantee:

- Seamless actuator integration in your design

- Increased efficiency of your design functionalities

- Significant time reduction for your project completion

Actuator Selection

To make sure your mission equipment works as we intend it to, we provide detailed description for your system in our Functional Design Specifications (FDS) document. In this document, we lay out how the hydraulic, electric, and software systems of the machine should operate. Thanks to our engineers’ involvement in the architecture of these systems, we can help you:

- Understand how exactly your machine should operate

- Select the procurement and define the technical specifications to build the D&C system

- Reduce error downtime and save time on designing commissioning all D&C components

- Set up operator training and create simulation software

Functional Design Specifications

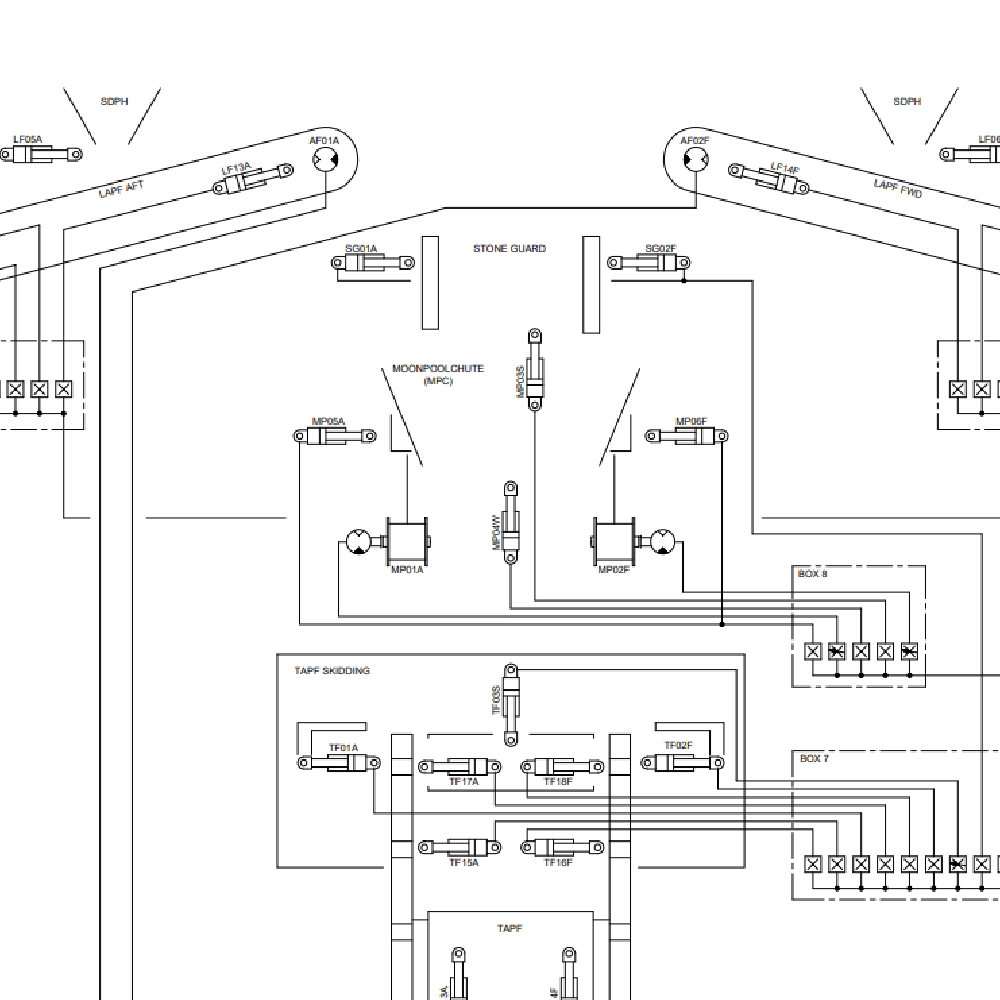

Once all the specifications are determined in FDS, we create single-line diagrams to portray the connections among the hydraulic, electric, and software systems. Through this detailed schematic representation of the functionalities, we act as a central communication point for your project and ensure that:

- All the parts of your machine come together perfectly

- All the systems are smoothly integrated into your machine thanks to our close collaboration with the sub-contractors

Single-Line Diagrams

It is crucial to accurately assess the function criticality of each system prior to the design. To make sure the safety of your design is never compromised, we take precautions such as hosting design risk assessment sessions and conducting failure mode effect analysis (FMEA). Our commitment to safety allows us to:

- Identify any risks that can impact your design

- Assess the potential risk effects that could happen to your project

- Make design adjustments at an early stage to mitigate those risks

Design Risk Assessment & FMEA

Operation Synergy

Built on the strength of TWD’s prominent presence in the offshore industry, our Drive and Control engineers work closely together with our in-house marine and mechanical experts. Together, we gain a thorough understanding of the marine environment in your project. We then incorporate this in our mechanical designs to deliver ingenious solutions. On top of this, our Drive and Control services can also stretch across the span of your project and contribute to methodology construction, fabrication assistance, and even on-site assistance. As a result, we bring you safe project execution with no waiting time and last-minute surprises.

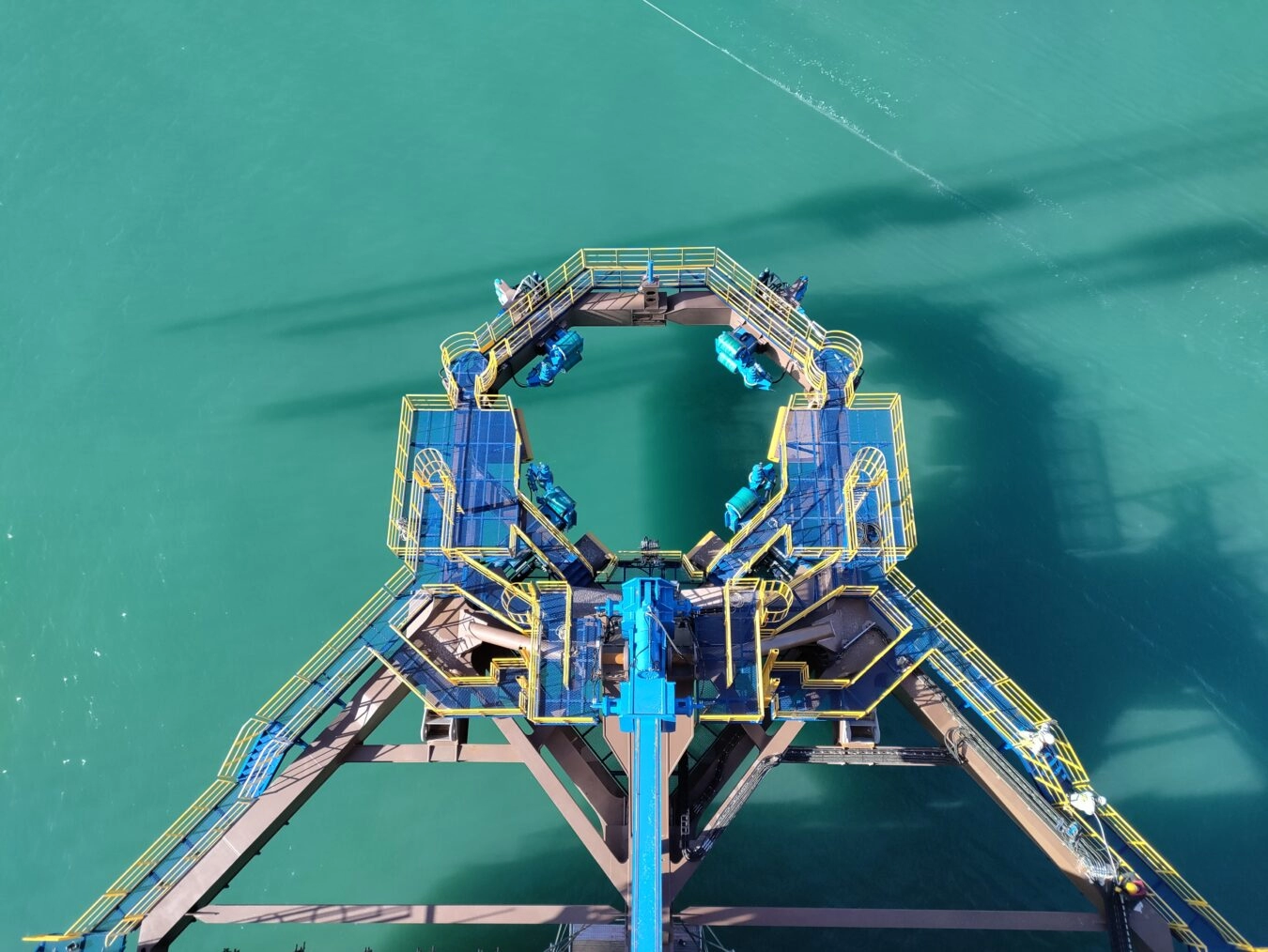

Motion Compensated Systems

To increase the safety and workability of your offshore projects, we have come up with various pioneering designs of motion-compensated systems. Gaining motion compensation expertise from our close collaboration with Barge Master, we have been able to revolutionize marine operations. Some of the perfect examples of our integrated solutions include the T-700 multi-purpose platform, the motion-compensated pile gripper, crane pedestal, and gangway. With the help of these ingenious and reliable engineering solutions, we assure you a safe, efficient, and quick offshore project operation.

Example Projects

Monopile Gripper – Hyundai Frontier

Read more

Cantilever Bridge – Western Australia

Read more

Start a project?

Curious about how you can benefit from our Drive and Control services? Reach out to us today and unleash the potential of your project.

Wesley de Groot