Software Engineering

At TWD, we not only excel in engineering and design, but also have a best-in-class software development team. Combining our coding capabilities with an engineering background gives us a unique standpoint when it comes to pinpointing and addressing some of the many inefficiencies in the maritime industry.

What began as an internal optimisation effort has developed into a multi-tier software and automation service. We provide tailored tools straight to the client. Think of Engineering apps to quickly perform strength verifications, check clashes, and generate reports, ready to go straight to the warranty surveyor. Or Design apps to develop mooring plans and brainstorm deck layouts. We’ve even started offering our Python based engineering platform to others, helping to accelerate development throughout the industry.

Our Products and Services

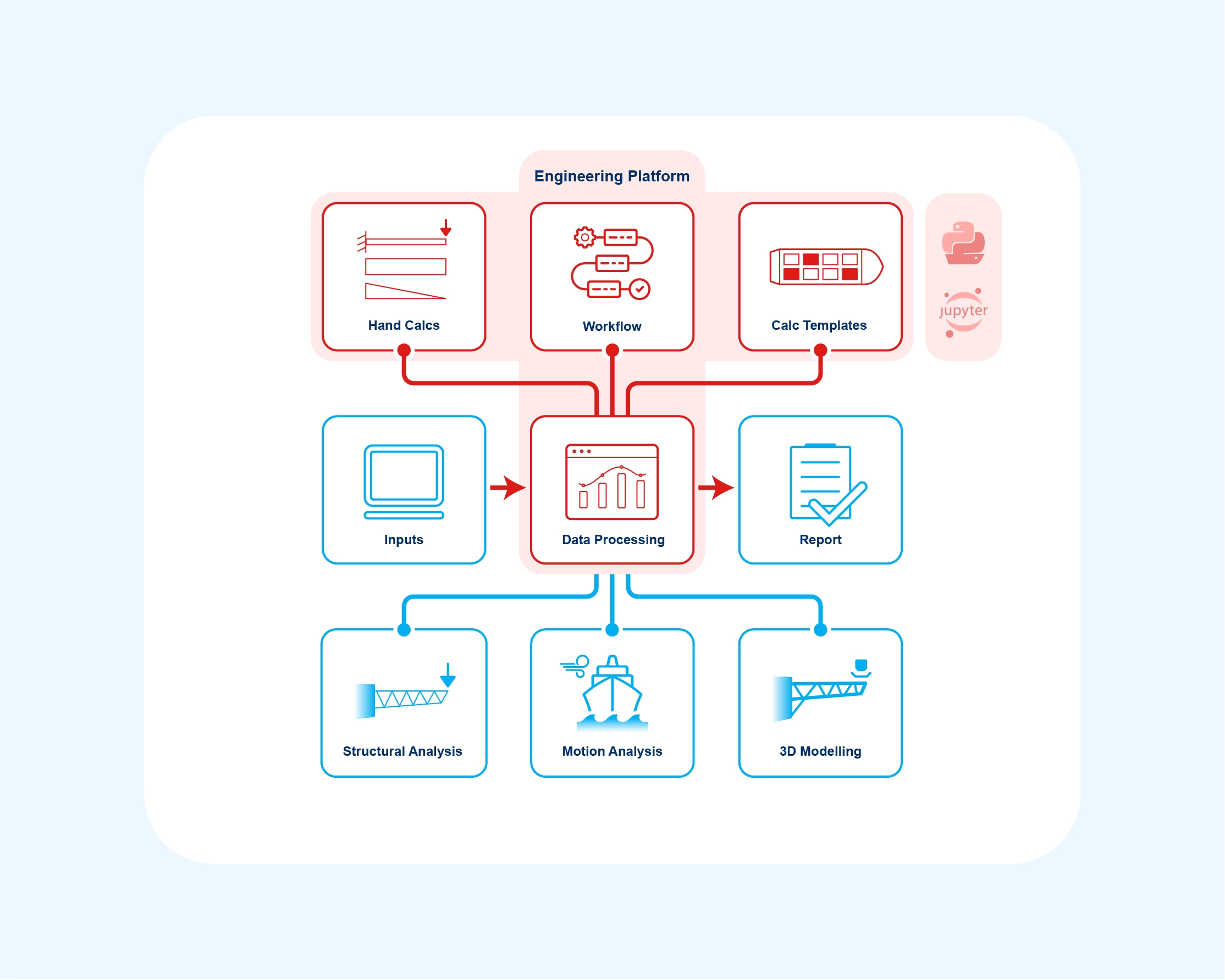

Thanks to our in-house Python package, our engineers can quickly perform calculations and produce well-structured reports with ease. Collaboration is straightforward and accessible through our cloud-based Python environment. In a nutshell, our approach allows us to:

- Quickly integrate new calculations

- Script repetitive, complex and heavier tasks

- Speed up flow and iterations by sharing data using SSOT (single source of truth) architecture

- Connect third party APIs and databases, and Integrate with design software like RFEM and Inventor

Over 100 engineers use our in-house Python platform on the daily. Recently, we also started offering this platform to others. Reach out if you feel limited by your current way of working, and want to hear more about our solution.

Engineering Platform

We packaged many of our engineering and design ingenuity as interactive, online apps. These allow us to quickly perform a standard analysis, or assess the feasibility of a certain operation. Could you benefit from something similar? Check out mot.twd.nl and try out some of our demo apps to get an idea of what we could build for you:

- Deck Layout

- Barge Stability

- Bollard Pull

- Spreader Beam

- MP Ops

Marine Operations Toolbox

The Monopile (MP) Operations Tool is a perfect example of how engineering, design, and software come together. In the app, the user can configure trips by selecting and positioning MPs on a vessel. The app then allows them to quickly:

- Check for clashes between holes/items on the MP and the deck components

- Verify the structural integrity of the deck components

- Verify the MP stability and integrity

- Determines the MP saddle settings

- Generate a report, including the trip sequence and the results of all checks

Using the app, the duration of these analyses are reduced from weeks to days. Last minute change request? Simply open up the app in a browser and update the configuration. It’s that simple.

Monopile Ops Tool

Automation at TWD

Our software journey started in 2015. That was the moment we decided to move on from spreadsheets and adopt Python as our go-to language. This allowed us to perform heavier and more complex calculations. It also opened the door to a plethora of new possibilities, like building a user interface in the browser, automating tasks, connecting third party software and database APIs, and combining output-input variables of separate calculations. Gone are the days spent manually copy and pasting: updates today require only a click of a button.

We then focused on our 3D modelling and technical drawings, automating repetitive Inventor and AutoCAD tasks. By drawing simple lines, we can generate full access models, bringing a week’s worth of work down to a couple of hours. More recently we invested in Autodesk Platform Services (APS), which allows AutoCAD-like software to be easily accessible in the browser – as seen in our Deck Layout Tool.

We’re always looking out for optimisation and automation opportunities within our way of working, and how they might be implemented in a smart way. Instead of going all-in with revolutionary procedures – foreign and disruptive to our day-to-day operations – our philosophy lies in empowerment: supplying teams with automation investments that promote gain with minimal effort or invasiveness. Most importantly, it allows our creative minds to outsource the repetition and concentrate on what we’re best known for – ingenious solutions.

Today, we work collaboratively with the goals of our clients and internal stakeholders, and pride ourselves in the delivery of reliable solutions every time.

Get in Touch

Want to discover the automation opportunity in your engineering operation? Reach out to our specialist.

Imco van Gent