Launching Girder

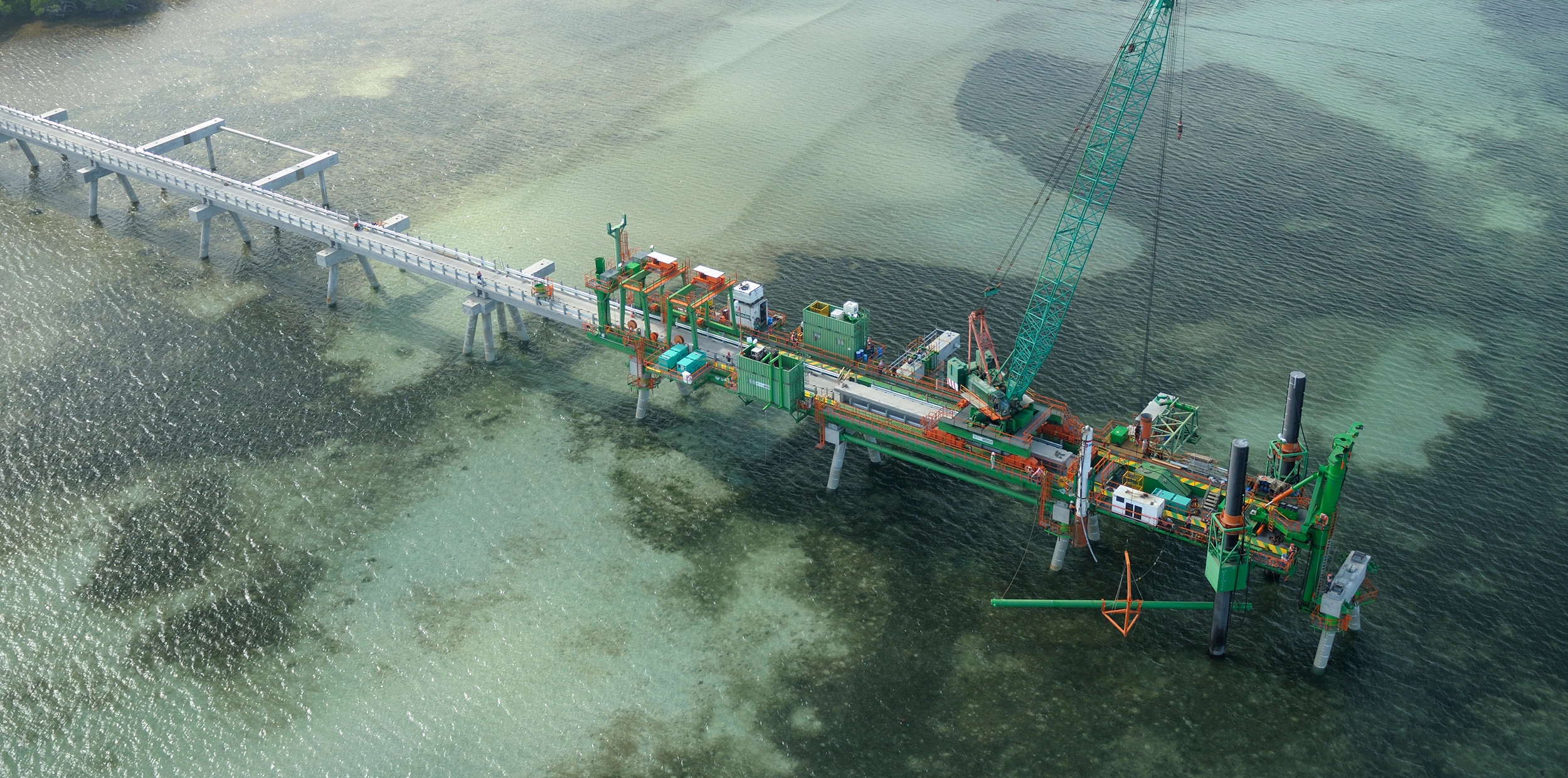

TWD has a proven track record in designing launching girders, commonly referred to as cantilever bridges, for a variety of near-shore marine infrastructures including jetties and bridges. These machines are tailored to the job and can be as simple as a skidding piling gate or as advanced as a complete mobile fabrication site.

Typically, the designs incorporate distinct workstations for tasks such as piling, concrete casting, welding, and lifting. As the girder travels over pre-installed works, we ensure that the structure is constructed independently of waves and tides. In this way, our approach offers an exceptionally efficient installation solution.

Featured Projects

LNG Jetty – Papua New Guinea

Read more

Cantilever Bridge – Western Australia

Read more

Piling and Drilling Template – Hay Point

Read more

Method Engineering

The launching girder, equipped with various integrated workstations, functions as a mobile fabrication site. Each workstation requires the supply of components such as concrete, steel, or pre-cast elements. During construction, the width between the main girders of the machine presents a limitation for the logistical operation. TWD’s multi-disciplinary engineering team can assist you in designing an efficient operational sequence, addressing logistics concerns, and eliminating potential bottlenecks.

Moving Forward

The substantial launching girder, with its several-thousand-ton weight and accompanying workstations, may require relocation over distances exceeding 40m between the headstocks. This can be achieved effectively and safely using methods such as winches, a skidding system, or a crane. This decision involves finding a balance between speed and the loads exerted on the permanent structure. At TWD, we work in closely with our clients and the permanent works designer to determine the optimal solution.

Piling

The bents of the jetty infrastructure comprise several tubular piles upon which the headstock is installed. Within the same project, the number, diameters, positions, and inclinations of these piles can vary. To move to the next position, the piling gate on the launching girder must accommodate various bent designs. Once the piles are driven to depth, the headstock is positioned and secured onto the piles. The piling gate must then be capable of moving aside to allow sufficient space for both the piles and headstock, considering the installed position and the forward movement of the launching girder. To address these challenges, the TWD engineering team has designed a range of nimble piling gates. Our dedicated team is prepared to tailor the optimal solution for your project needs, enhancing both safety and efficiency.

Happy to Assist with Your Next Challenge

TWD is an international engineering company rooted in Rotterdam, the Netherlands, since 2007. Committed to Making Construction Easier, we have partnered with industry leaders such as BAM, VolkerStevin, Graham, and SRGB, providing ingenious method engineering and customized equipment designs. Don’t hesitate to contact us to discover how our tailored launching girder solutions can streamline your construction projects. Alternatively, download our Track Record for further insights.

Related Solutions

Caisson Transport and Installation

Read more

Marine Piling and Drilling

Read more

Immersed Tunnels

Read more

Starting a project?

Curious about how we can help you with your next project? Reach out, and let us show you how.

Cyril Girardeaux