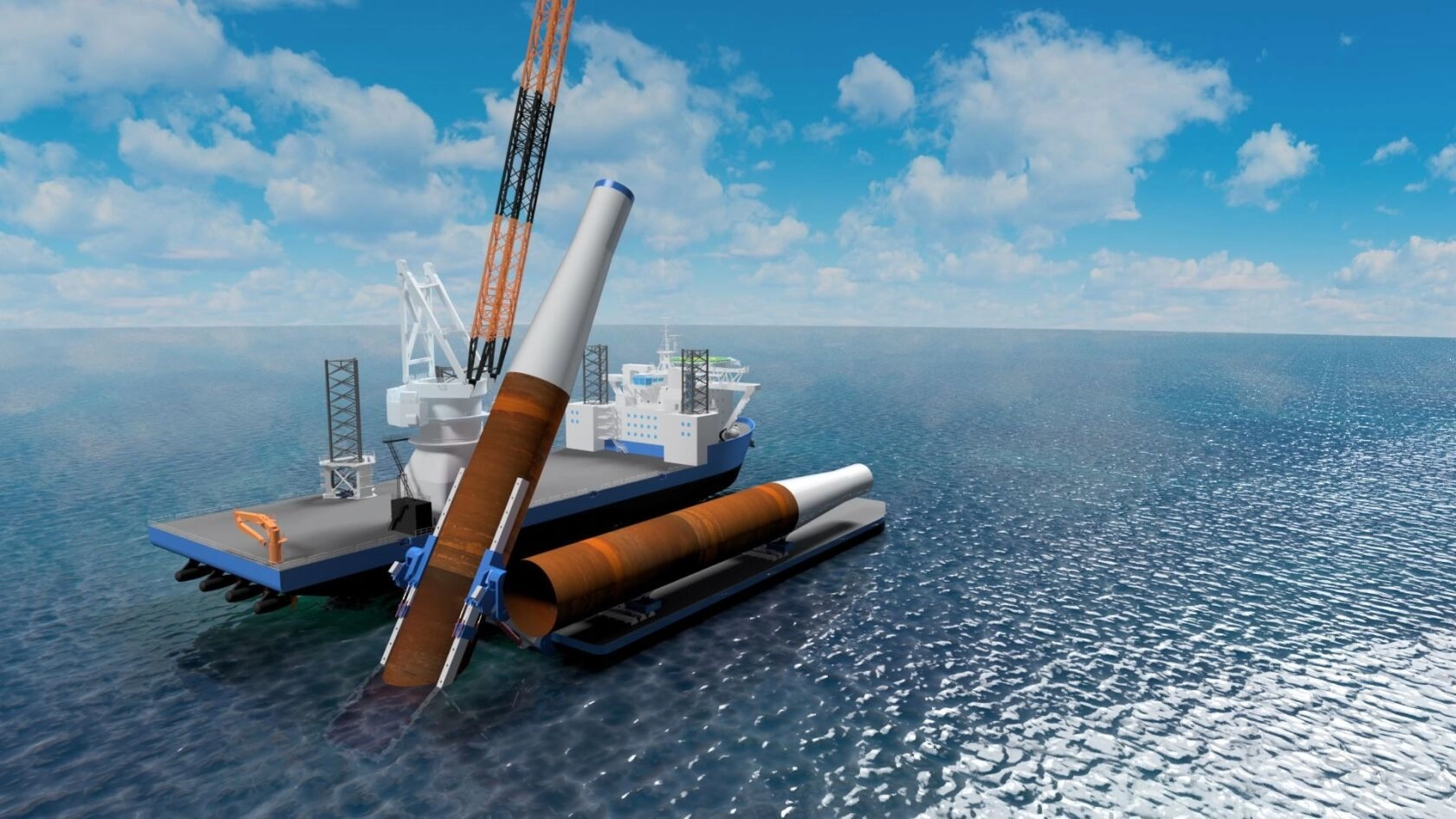

Upending Hinge

Our upending solutions facilitate a controlled, stable and safe operation. With 15 years of experience, TWD delivers customized solutions for every pile or object that needs to be up or down ended, whether it’s on a heavy lift vessel, jack-up, barge, or on land.

Our expertise ensures that we tailor functional solutions to meet the specific requirements of your project. Considering offshore dynamics, we ensure that the operation is conducted within the required workability limits and timeframe. These unique upending designs have contributed to the successful installation of many piles, such as pin piles for jackets, or monopiles.

Featured Projects

Seafastening Structures for Yunlin OWF

Read more

Adjustability for Pile Diameters

Within each project, monopiles and pin piles are optimized to suit the installation site conditions, resulting in variations in pile lengths and diameters. TWD has designed many customized upending mechanisms capable of accommodating various pile diameters, reaching up to 12.5 meters. These mechanisms range from project specific and cost-effective filler blocks to future proof and rapidly operated remote-controlled jacking systems.

Adjustability for Pile Lengths

In addition to the differing diameters, the lengths of the piles can also vary significantly. For instance, when a heavy lift vessel is installing long piles, this presents challenges regarding the crane capacity and height during the initial stages of the upending operation. For such a case, a long stick-out of the upending hinge can be an effective solution to bring the top of the pile closer to the crane. Additionally, to facilitate the installation of smaller piles, the upending hinge bottom beam can be made telescopic.

Challenges of The Dynamic Environment

Ensuring a safe upending operation offshore, with optimal workability, requires a good understanding of environmental loads and vessel behavior. This is especially important for floating installation vessels, where piles are upended through the splash zone amidst the vessel motions. Leveraging calculations and simulations, we have developed an expert understanding of these operations,. enabling our clients with the offshore workability limitations they require.

Tailored Solutions

Project specific requirements lead to variation in installation methods and assets. TWD’s extensive track record in upending designs includes solutions for autonomous and craneless upending of piles. Additionally, we designed upending hinges with lowering mechanisms, enabling the skidding the piles from seafastening position into the upend line. These are just a few examples of tailored functionalities that we offer. Feel free to get in touch with us to discuss how our upending solutions can enhance the safety and cost-effectiveness of your operation.

Happy to Assist with Your Next Challenge

Over the past 15 years, we take pride in our involvement in more than 100 offshore wind farms worldwide. From upending hinges and piling templates to WTG seafastening and cable lay carousels, our multidisciplinary engineering teams are ready to tackle any challenge. Whether you are seeking custom solutions or future-proof designs, we are here to assist. Reach out to us to explore how our upending solutions can enhance the safety and cost-effectiveness of your operations. Alternatively, download our Track Record for future insights.

Related Solutions

Secondary Steel Installation Tools

Read more

Monopile Seafastening

Read more

Monopile Gripper

Read more

Starting a project?

Curious about how we can help you with your next project? Reach out, and let us show you how.

Wesley de Groot