Jacket Lifting Tool

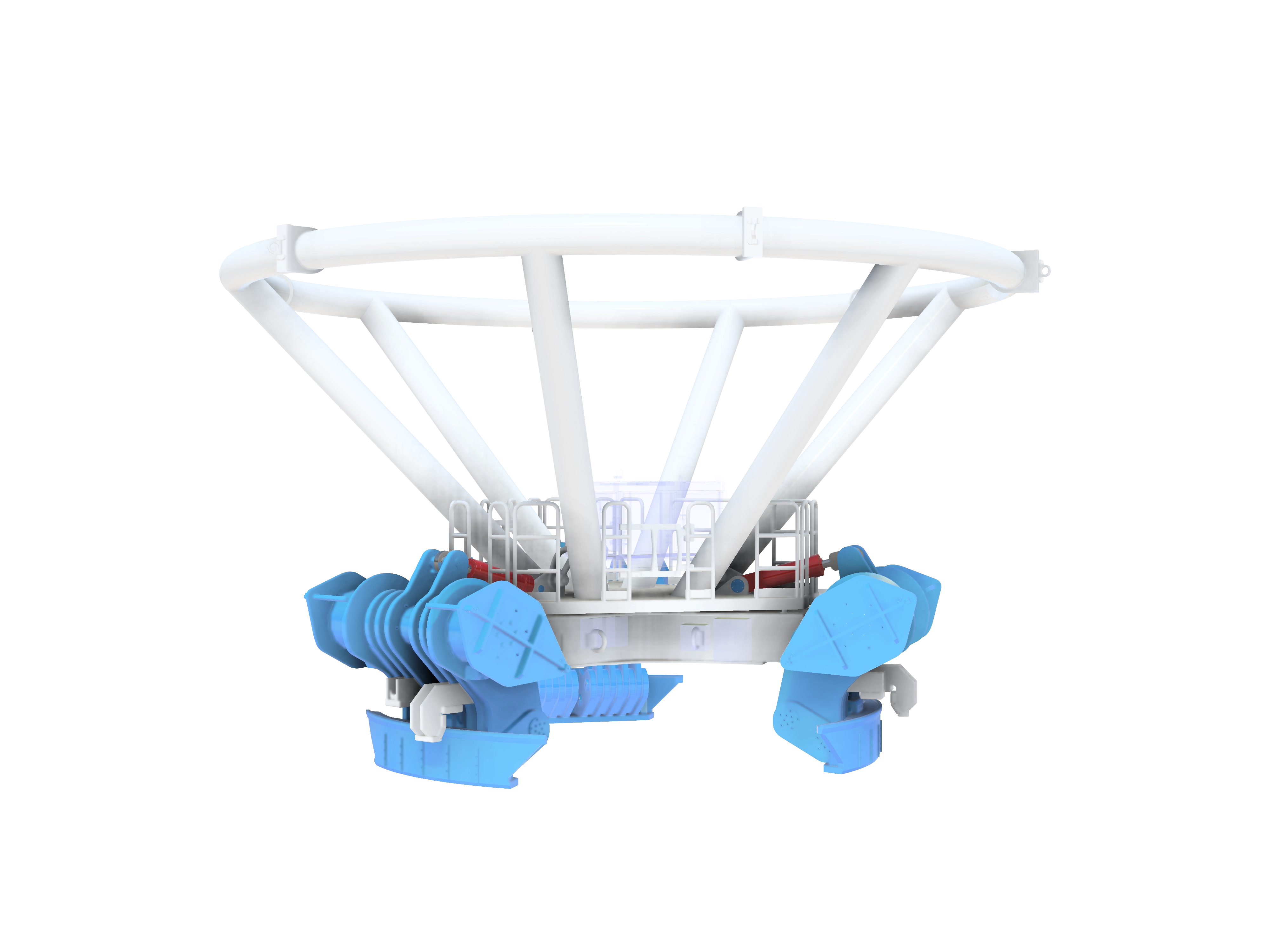

TWD designs a diverse range of Jacket Lifting Tools, ensuring the secure lift of jackets, either internally, at the flange, or externally, at their dedicated lifting pad-eyes.

We develop tailored solutions to match the unique characteristics of each jacket, crane specifications, and the demands of the offshore operation. Our dedicated team is there to support you from tendering stage to mobilization stage. We use smart load test methods and cost-effective transportation solutions to ensure operational efficiency.

Featured Projects

Jacket Flange Lifting Tool – TPC II

Read more

Jacket Lifting Tool – East Anglia One

Read more

Method Engineering

For a safe and efficient lifting operation in offshore environments, it is crucial to understand environmental loads and movements of both jackets and vessels. This is especially important for floating installation vessels, where jackets move through the splash zone during vessel motions.

The dynamic setting often causes significant off- and side-lead in the crane, affecting the performance of the jacket lifting tool. Using calculation and simulation techniques, we have developed expertise in these operations, providing clients with precise answers for seamless offshore operations.

Flange Integrity

As jacket sizes and weights have increased in recent years, TWD has observed a corresponding challenge: while jacket dimensions expand, flange sizes are not growing accordingly. Ensuring the integrity of these flanges is an increasing challenge. Our team of structural engineers creates customized solutions to address this concern. By providing extra support in the area near the can-section, we make sure the plastic strain is kept within allowable limits. Additionally, TWD conducts flange integrity tests for third-party tools, offering comprehensive support in all areas.

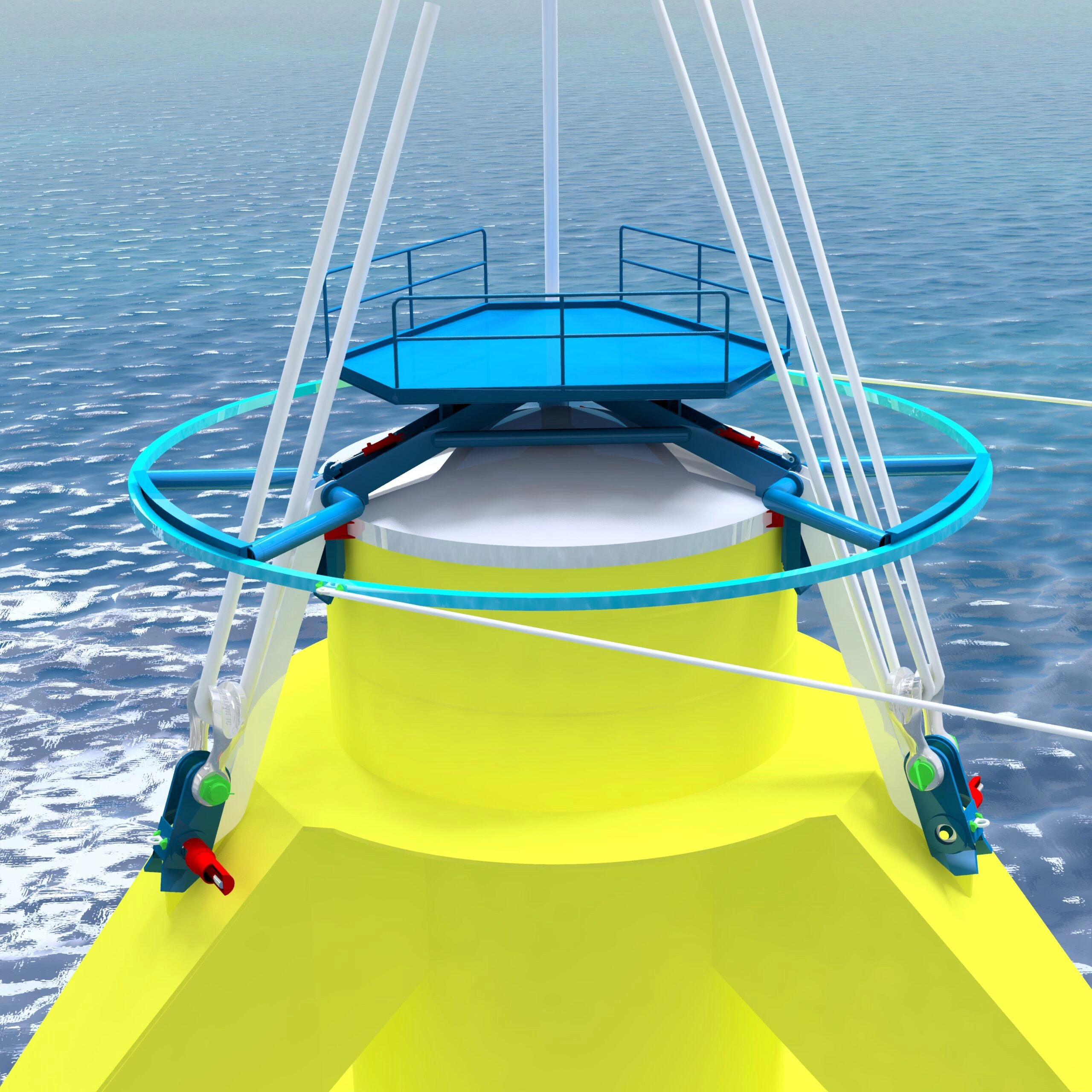

Lifting Tool Guidance

When dealing with floating installation vessels, it is essential to have a robust procedure for guiding the lifting tool into position. This crucial operation often leads to weather-related delays or unintended damage to jacket cranes and coatings.

We specialize in designing easily removable bumper and guiding structures for jacket flanges. These are paired with robust tuggers, safeguarding your operations, and maximizing efficiency.

Safety in Design

A safe and robust link between jacket and lifting tool is the basis of a good design. At TWD, we employ self-locking design principles to guarantee the lifting tool clamps always engage with the flange. This happens when the jacket weight is applied. As an extra layer of safety, we can incorporate additional active locking pins or mechanisms.

Happy to Assist with Your Next Challenge

Our innovative engineering designs have contributed to the successful installation of hundreds of jackets, strengthening our position as an industry leader in offshore lifting solutions. Download our Offshore Wind Track Record to learn about how TWD assisted top-tier companies such as DEME, Van Oord, HESI, Jan de Nul, and Shimizu succeed in their Offshore Wind installations. Feel free to contact us to schedule a consultation and explore further.

Related Solutions

Pre-piling / Drilling Template

Read more

Jacket Seafastening

Read more

Pin Pile Seafastening

Read more

Starting a project?

Curious about how we can help you with your next project? Reach out, and let us show you how.

Wesley de Groot