Pre-piling / Drilling Templates

Our custom pre-piling and drilling templates are designed to ensure a safe and efficient installation of pin piles for your jacket structures. At TWD, we have extensive experience in piling template design.

Our process begins with detailed fatigue analysis tailored to operational parameters, and vibration assessments, ensuring pin pile integrity throughout operations. We provide bespoke lifting connections and seafastening designs based on dynamic studies, considering environmental factors. We also perform comprehensive soil bearing calculations to optimize mudmat performance, ensuring reliability and durability for your offshore installations.

Featured Projects

Method Engineering

We collaborate closely with our clients throughout every phase, tailoring the best solutions for each project from the start. This may include:

- Evaluating the benefits of Heavy Lift Vessels versus Jack-up operations

- Comparing the pros and cons of Impact Hammers versus Vibro Technologies

- Refining pile stabbing sequences

Our feasibility studies consider diverse soil conditions to determine the optimal template foundation. These insights enable us to provide early cost and lead time estimates, empowering informed decision-making.

Tailored Template Design

Our template designs are versatile, reusable, and adaptable, tailored to fit a wide range of jacket sizes. This flexibility enables the accommodation of different pin pile diameters with ease. Whether you choose fixed or adjustable shims, our templates can be customized to fit various pin pile types and sizes.

Additionally, both options can be equipped with leveling cylinders, ensuring pile verticality on sloped seabeds. We engineer mudmats to withstand soil bearing loads while mitigating slamming loads and suction forces during retrieval, ensuring peak performance in diverse conditions.

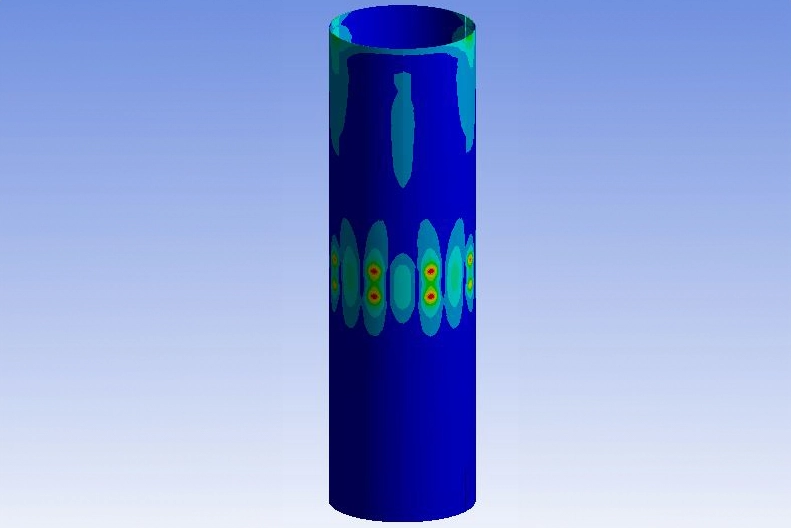

Fatigue Studies

With fatigue analysis, we examine the operational and environmental loads, including vibrational fatigue, ensuring reliability throughout your project’s lifecycle. Our templates are designed to withstand fatigue, even in the most demanding conditions. We conduct detailed fatigue studies to check and validate the durability of our templates, making sure they provide a reliable and solid contribution to your project.

Dynamic Studies

We perform detailed dynamic analyses to determine the forces acting on both the piles and the template throughout their operational lifespan. This allows us to optimize the template design in weight and size. Our workability studies provide valuable insights into the uptime of templates, further enhancing their effectiveness.

Happy to Assist with Your Next Challenge

TWD stands as a leading engineering company, with a proven track record in creating advanced pre-piling and drilling template equipment. Our engineering teams specialize in overcoming unique market challenges, delivering innovative and personalized solutions.We expertly merge method engineering with equipment design to achieve outstanding outcomes.

Related Solutions

Secondary Steel Installation Tools

Read more

Monopile Seafastening

Read more

Monopile Gripper

Read more

Starting a project?

Curious about how we can help you with your next project? Reach out, and let us show you how.

Wesley de Groot