Monopile Lifting Tool

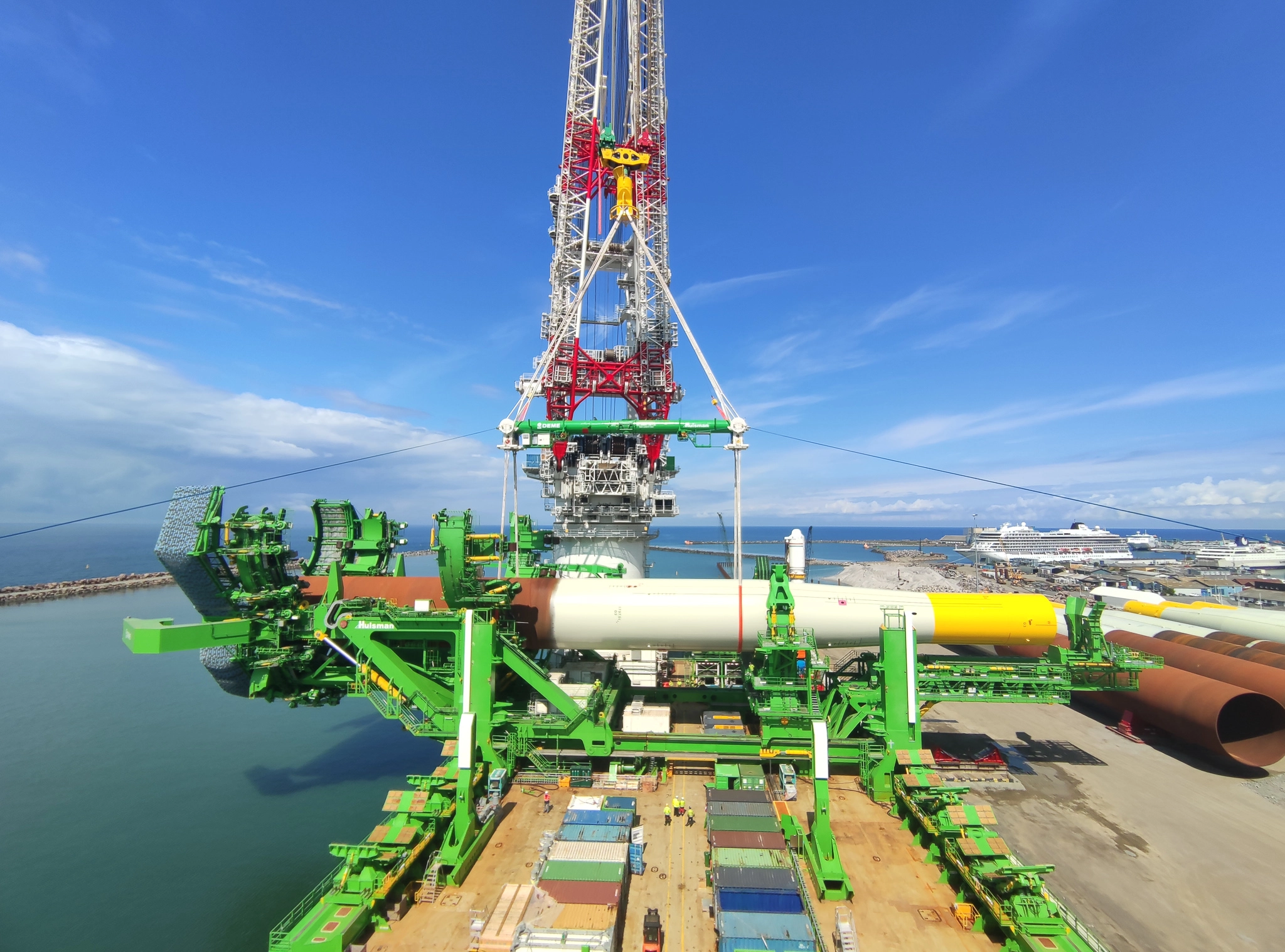

TWD has designed many different flanged pile upending tools (FPUT), also known as Monopile Lifting Tools, enabling the safe upending and lifting of monopiles.

We design customized solutions to the range of piles, the crane, and the offshore operation. By considering the specific requirements of dynamic offshore operations and ensuring that designs align with our client’s workability limits, we have contributed to the installation of hundreds of monopiles with our unique designs.

Featured Projects

Pin Pile Lifting Tool for TPC II

Read more

Flanged Monopile Upend Tool

Read more

Method Engineering

To ensure a safe upending and lifting operation, with optimal workability in offshore environments, a good understanding of both environmental loads on monopile and vessel behavior is required.

This is especially important for floating installation vessels, as the piles are upended through the splash zone while contending with vessel motions. The dynamic environment can lead to significant off- and side lead in the crane, affecting the Monopile Lifting Tool.

Through calculation and simulation, we have acquired an expert understanding of these operations, providing tools that grant the offshore workability specifications our clients require.

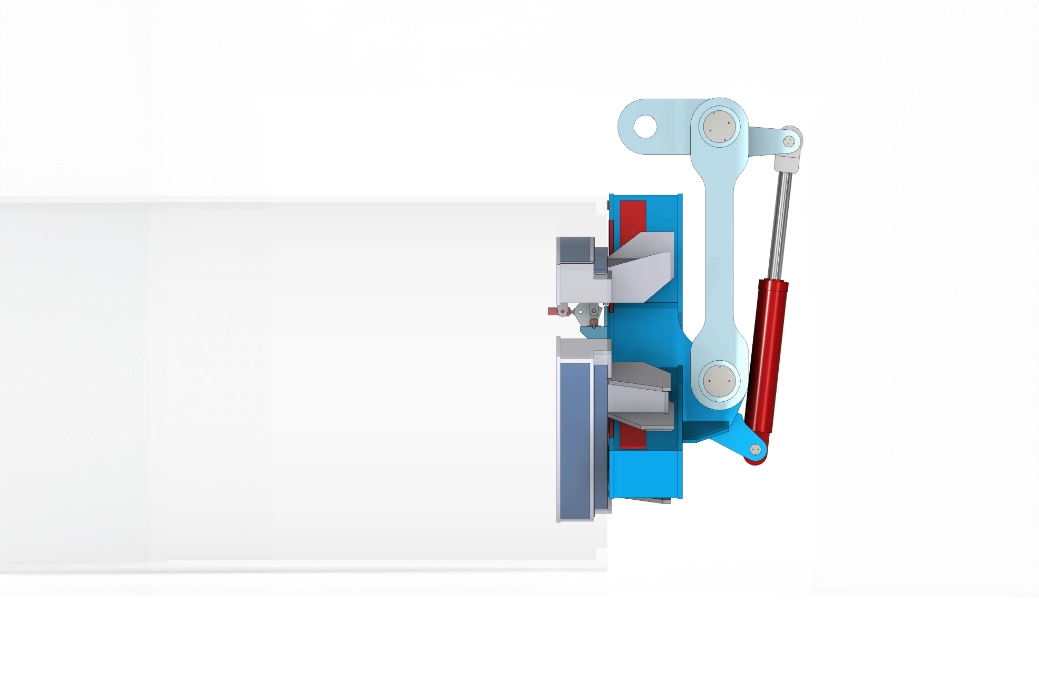

Functionality vs. Lightweight

Because of the ever-increasing monopile weight, the weight of the lifting tool itself – and it’s rigging – must be as light as possible.

Our tailored lifting tools can be designed to include functionalities like future proofing diameter ranges, modularity for road transport, robust guidance structures, and remote actuated rotation.

Flange Integrity

Over the years, TWD has seen a rapid increase of Monopile size and weight. Flange dimensions do not always grow at the same pace, making it an increasing challenge to secure flange integrity. Our structural engineers develop tailored solutions to gain sufficient flange support area as close as possible to the monopile can section, ensuring the plastic strain of the Monopile is kept within allowable limits. We also offer these services to check flange integrity for third-party tools.

Lifting Tool Stabbing

In floating installation vessels, or float-to-float operations, it is crucial to have a robust monopile stabbing procedure.

This operation is often the source of downtime or unwanted monopile coating damage. TWD has designed bespoke monopile stabbing solutions, typically using large bumpers and guides on the lifting tool, combined with tuggers and/or an additional guiding and stabbing tool near the top of the monopile.

Happy to Assist with Your Next Challenge

TWD is a leading engineering company rooted in Rotterdam, the Netherlands. Since 2007, we have accumulated a large track record in tailored solutions for offshore wind farm installations. From Japan and Taiwan to France and the United Stages, our multidisciplinary engineering teams have contributed to over 100 wind farms. Explore our Track Record to discover how we can assist in creating your Monopile Lifting Tool. Alternatively, feel free to plan a consultation for a quick project discussion.

Related Solutions

Secondary Steel Installation Tools

Read more

Monopile Seafastening

Read more

Monopile Gripper

Read more

Starting a project?

Curious about how we can help you with your next project? Reach out, and let us show you how.

Wesley de Groot