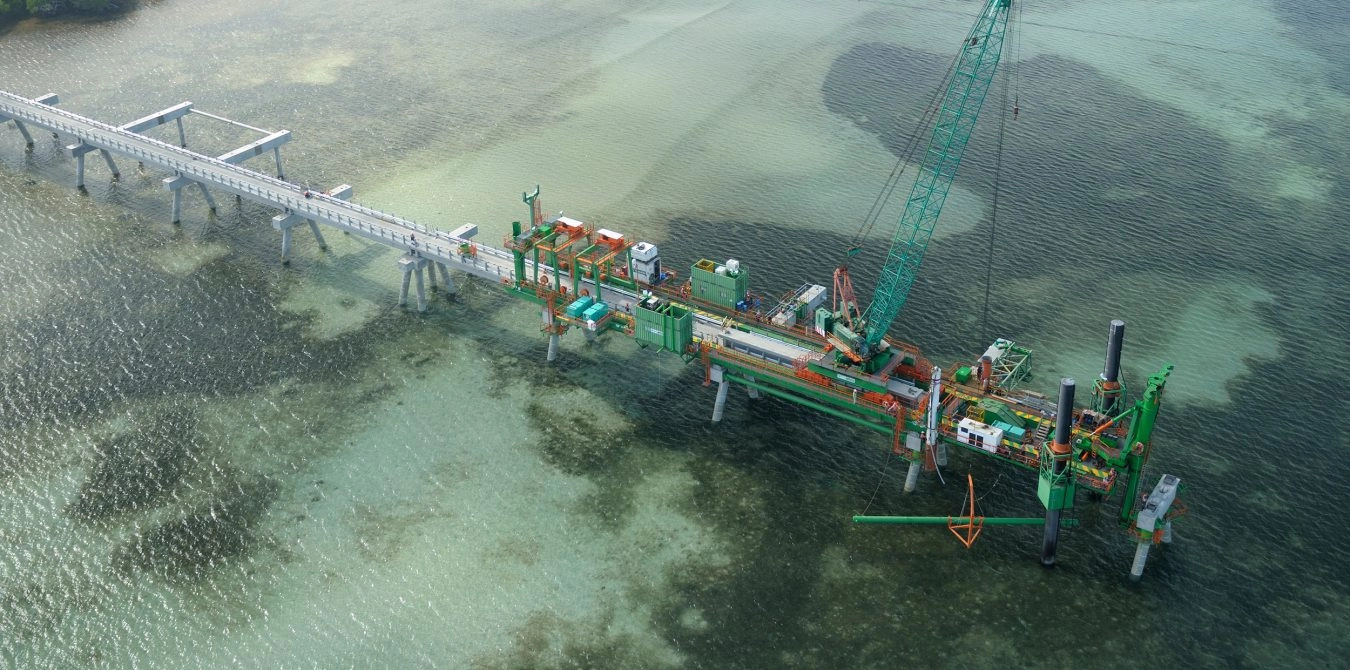

Caisson Transport and Installation

Caisson structures are vital for underwater foundations in port development, breakwater expansion, and repairs. TWD excels in these projects, with experience handling caissons ranging from a few hundred tons to over 20,000 tons.

We offer comprehensive, tailored support for any caisson installation, regardless of weight or equipment requirements. Our expertise includes caisson transport, installation method engineering, and the design of temporary equipment such as mooring bollards, pump frames, boat landings, skidding, and seafastening. Additionally, we provide 3D hull strength analyses and reinforcement designs.

Featured Projects

Transport and Installation Method Engineering

Caisson logistics, particularly transportation and installation methods, pose substantial challenges. Leveraging extensive expertise, TWD supports you from tender through pre-FEED and FEED phases, assisting early in the project. Our multi-disciplinary team, together with logistics experts, marine operations managers, captains, engineers, and fabrication specialists, ensures tailored solutions and precise time and cost estimates for caisson projects of any scale. From assessing port strength and space availability to optimizing skidding sequences and offshore transport, TWD excels in method engineering. Whether for a single caisson or a large-scale project like the 245 caissons in Morocco, you can trust TWD for optimized solutions.

Vessel Selection and Engineering Assessments

The selection of the right vessel for caisson transport is crucial for project success, either streamlining or complicating operations. TWD’s specialists support you in vessel selection, offering advice at every project stage to streamline processes and minimize effort. We assess deck strength during project preparation and design under-deck reinforcements as needed. Our teams conduct thorough vessel checks using proprietary and industry-standard tools. Additionally, we provide mooring assessments and tailored ballast plans for each project phase, optimizing efficiency for clients, surveyors, and operational staff.

Caisson Support Structures Design and Engineering

Integrating temporary equipment with caissons is a complex operation requiring close collaboration between caisson and equipment designers to align on water head differences, structural capacities, and early-stage modifications. TWD aims for designs that are reusable across multiple caissons and are non-sacrificial, allowing equipment to be removed after installation and reused for subsequent caissons.

Get in Touch With TWD for Your Next Caisson Project

With an extensive track record in marine civils and offshore projects, TWD provides high-level method engineering and project-specific equipment design. Anticipating project needs and bottlenecks, our global team of over 250 engineers ensures timely support, delivering dedicated engineering reports, design drawings, method statements, and installation plans. Feel free to contact TWD for your next caisson transport and installation project.

Related Solutions

Starting a project?

Curious about how we can help you with your next project? Reach out, and let us show you how.

Cyril Girardeaux