Secondary Steel Installation Tools

Drawing on more than 15 years of expertise, TWD has developed a range of bespoke tools specifically designed to streamline and simplify the installation of secondary steel components for foundations.

Offshore wind farms increasingly opt for extended monopiles with secondary steel components over traditional monopiles with transition pieces. This transition simplifies the design and fabrication of primary steel and poses unique challenges for installing secondary steel components like anode cages, boat landings, internal and external platforms. To overcome these challenges, TWD works closely with clients to develop an optimal set of installation tools tailored to their specific installation methodology.

Featured Projects

Increased Installation Efficiency

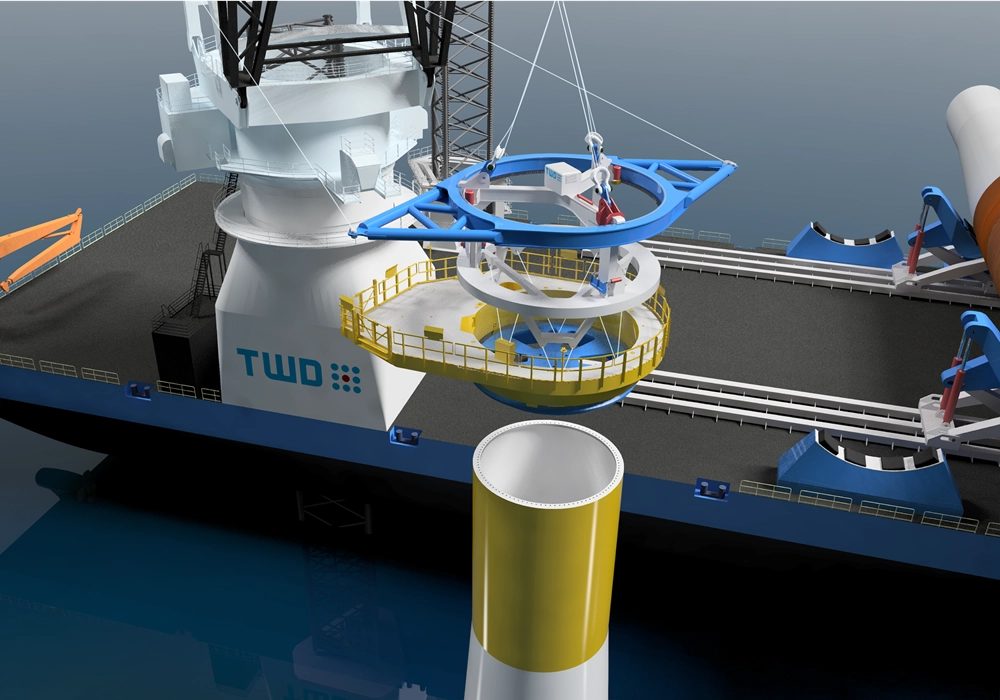

When installing various secondary steel components on a monopile, combining multiple components in a single offshore lift using the same installation tool can significantly reduce both the number of offshore lifts and the installation tools required. TWD has developed a versatile range of installation tools capable of installing one or more secondary steel components in a single lift. These tools streamline the process, minimize the number of offshore lifts required and thereby reduce the overall installation time for secondary steel components. An example of this can be seen in the left image, where TWD designed a Secondary Steel Installation Tool for the Hollandse Kust Zuid OWF. This tool enabled the installation of the internal platform and boat landing in a single offshore lift.

Future-proof Tools for Flexible Installation

As the use of secondary steel components grows in the offshore wind industry, their size and design often vary from one wind farm to another, leading to complex, project-specific installation tools.

TWD tackles this challenge by enhancing the flexibility of secondary steel installation with our innovative solutions. Our Modular Secondary Steel Installation Tools and Modular Tugger Frame are designed to simplify and future-proof the installation process, accommodating diverse project requirements.

Modular Secondary Steel Installation Tool

The Modular Secondary Steel Installation Tool (SSIT) is designed for use across various projects, enabling the installation of multiple secondary steel components in a single offshore lift. It can lift and install the internal platform, anode cage, and boat landing – all remotely controlled – in one lift. The SSIT stands out from traditional tools with its modular frame, which can be customized to accommodate different secondary steel designs and monopile diameters. This adaptability ensures that the SSIT is effective for a range of offshore wind farms, regardless of the design or size of the components.

Modular Tugger Frame

The Modular Tugger Frame (MTF) integrates the complex functionalities needed for installing various secondary steel components. It complements simple, cost-effective installation tools that securely hold and guide the components onto the monopile. Its adaptable design allows the MTF to function independently of the secondary steel design, making it reusable across various projects. By increasing installation efficiency and reducing the need for multiple complex tools, the MTF streamlines the installation process.

Happy to Assist with Your Next Challenge

TWD has been a leading engineering company since 2007, specializing in the design of secondary steel installation tools. With a proven track record supporting over 100 wind farms globally, we excel in addressing market-specific challenges through our innovative and robust solutions. Explore our Offshore Wind Track Record to see how we can enhance your project with method engineering and equipment design. Whether you need custom solutions or future-proof designs, we are here to help.

Related Solutions

Wind Turbine Seafastening

Read more

Wind Turbine Feedering

Read more

Monopile Seafastening

Read more

Starting a project?

Curious about how we can help you with your next project? Reach out, and let us show you how.

Wesley de Groot