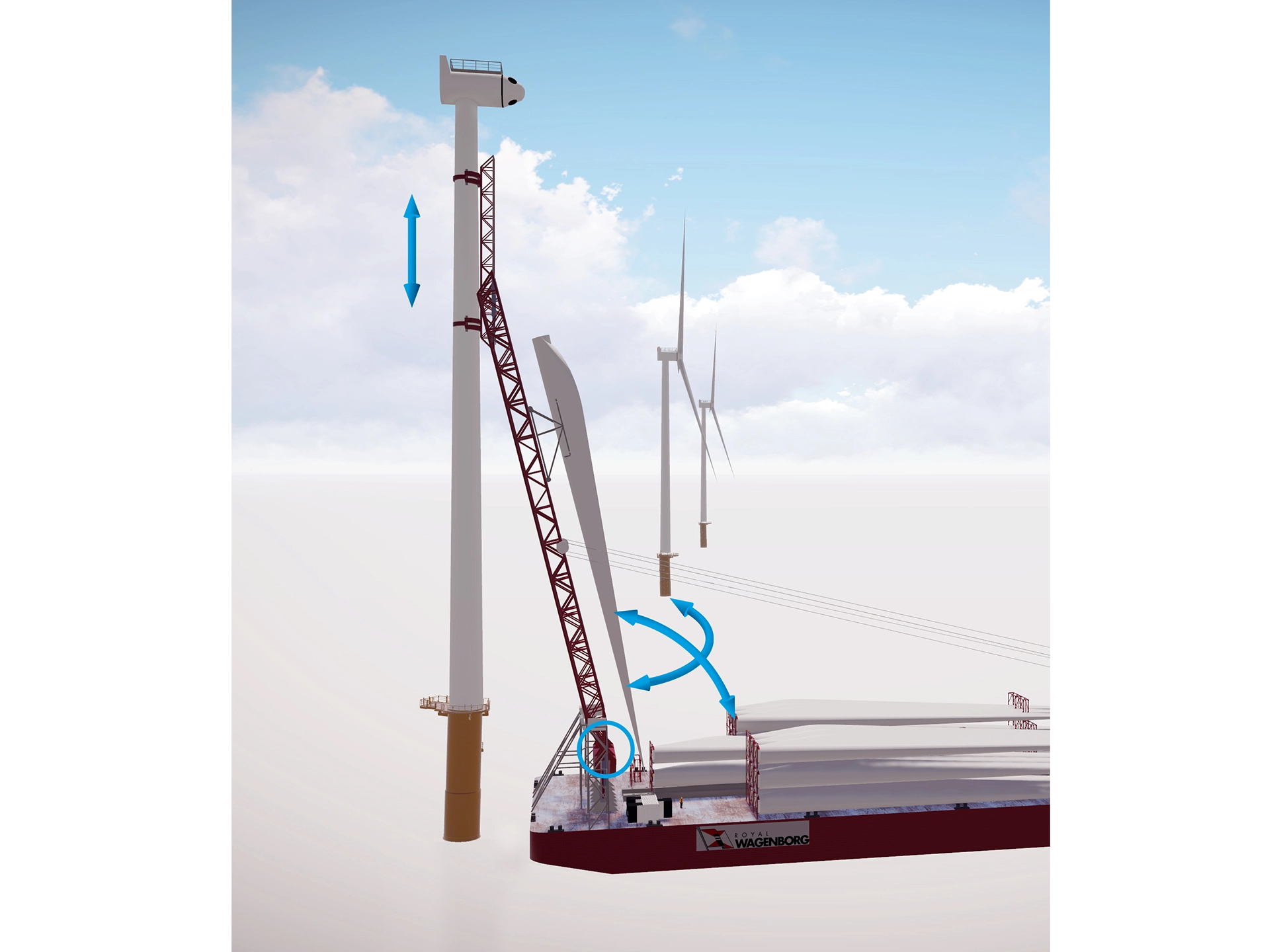

Innovation – Blade Exchange Tool

Innovative exchange of WTG components

The demand for expected and unexpected maintenance work increases with every newly installed offshore wind turbine. With a potential of more than 5.000 sub-5MW blades needing to be exchanged, finding a cost-effective solution has become a necessity. One solution is to replace the jack-up vessel with a floating solution with similar workability. This can significantly save cost and time. That is why, TWD, together with Royal Wagenborg, have come up with an innovative floating removal and installation method.

The vessel independent tool is equipped with a motion compensation system to mitigate relative motions during turbine approach and allows for a safe connection. Once connected, a smart blade handling cart can collect, transport, and place blades and other heavy components of the nacelle. Due to its innovative character, the tool brings increased workability compared to other lifting solutions.

Project highlights

- Low day-rate barge or vessel

- Large deck space

- Perform repairs offshore advantages

- Vessel independent; on barge or vessel

As the global wind energy sector expands, a shortage of vessels for handling bigger monopiles is foreseen. Simply scaling up isn’t enough. Download our Whitepaper to explore how TWD tackles supply chain bottlenecks with innovative installation methods, or get our Offshore Wind Track Record to see how we have helped industry leaders succeed in their installations.