Geotechnical

Engineering

Thanks to the seamless collaboration with our in-house structural and marine experts, our geotechnical engineers can bring significant extra value to your project by improving designs, safety, cost-effectiveness, and workability.

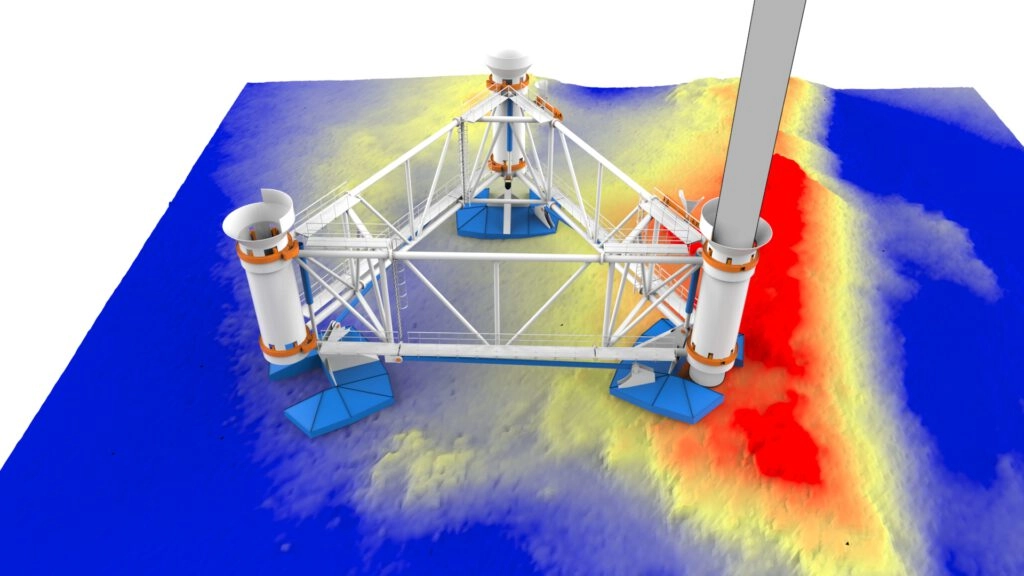

Whether it is a (pre-)piling template, temporary dam, subsea tool, or a monopile gripper, temporary works often have interfaces with the subsoil or existing foundations. Since local soil conditions can significantly impact equipment design, operational risk and project workability, geotechnical challenges require solid expertise and in-depth knowledge. With the analysis from our dedicated geotechnical engineers, we bring you lean and integrated equipment designs for your next engineering project.

Our Expertise

A properly designed foundation is a necessity for creating safe and effective mission equipment. Performing foundation engineering ourselves allows TWD to make tailored equipment designs for your projects. As our geotechnical engineers, advisors, and designers work together, any changes on your end can be quickly communicated, assessed, and updated. Because of our open and transparent work approach, we collaborate closely with your project team during the entire engineering and design process.

We can support your foundation design with:

- Bearing and sliding envelopes for shallow foundations

- Settlement and deformation analysis

- Axial and lateral pile design

- Temporary sheet pile and cofferdam design

Foundation Design

Structures such as a mud mat, (pre-)piling template, or a barge mooring temporary pile all interact with the local soil conditions. Soil structure interaction, therefore, has a significant impact on the workability and feasibility of your operations. Thanks to our multidisciplinary approach, we can provide you with fast input at an early stage of your design. By doing so, safe and proper calculations on the performed operations are assured.

We take care of your soil structure interaction by providing services such as:

- Self-stable embedment depth and on bottom stability analysis

- Stiffness representations for dynamic models

- Drive-ability and self-weight penetration

- Soil structure interaction models for structural design

Soil Structure Interaction

Atypical soil conditions can have a large impact on your project for both design and operations. The occurrence of scour, liquefaction, challenging bathymetry, or pile run due to a weak soil layer should be foreseen. Our geotechnical engineers can spot these failure mechanisms at an early stage of your project, addressing the issue in our designs, and create a tailor-made mitigation measurement for you.

We assist you to collect survey data and conduct operational risk analysis via:

- Bathymetric survey interpretation

- Soil profile identification

- Operational risk assessment

- Tailor-made mitigation measures and safety approach

Survey Data & Operational Risk Analysis

Working with TWD

At TWD, we aim to make your construction project easier. By combining smart method engineering with creative equipment design, we bring safe, efficient, and tailored solutions to your project’s construction, installation, or transportation methods. Thanks to our multidisciplinary engineering approach, we take care of your technical risks at scope splits. By doing so, we guarantee an integrated equipment design solution.

Operation Synergy

Our geotechnical engineers combine their in-depth knowledge of soil conditions with the expertise of our various in-house services to attend to every interface of your project carefully. Through close collaboration, TWD’s engineering disciplines conduct detailed geotechnical analysis. Based on this, we develop the most optimized and fit-for-purpose designs.

Thanks to our integrated way of working, we work out smart solutions that guarantee safe, cost-effective, and timely project completion.

Start a project?

Want to know more about how we can apply geotechnical engineering to your next project? Let us show you how.

Wesley de Groot