Structural Design for Mampaey’s Intelligent DockLocking System

Following new regulations from the London Port Authority to make the Thames ferry services more environmentally friendly, the ferries must cut their engines when docked. Since using conventional mooring lines consumes too much time, a fast automatic docking solution was required to meet the new regulations.

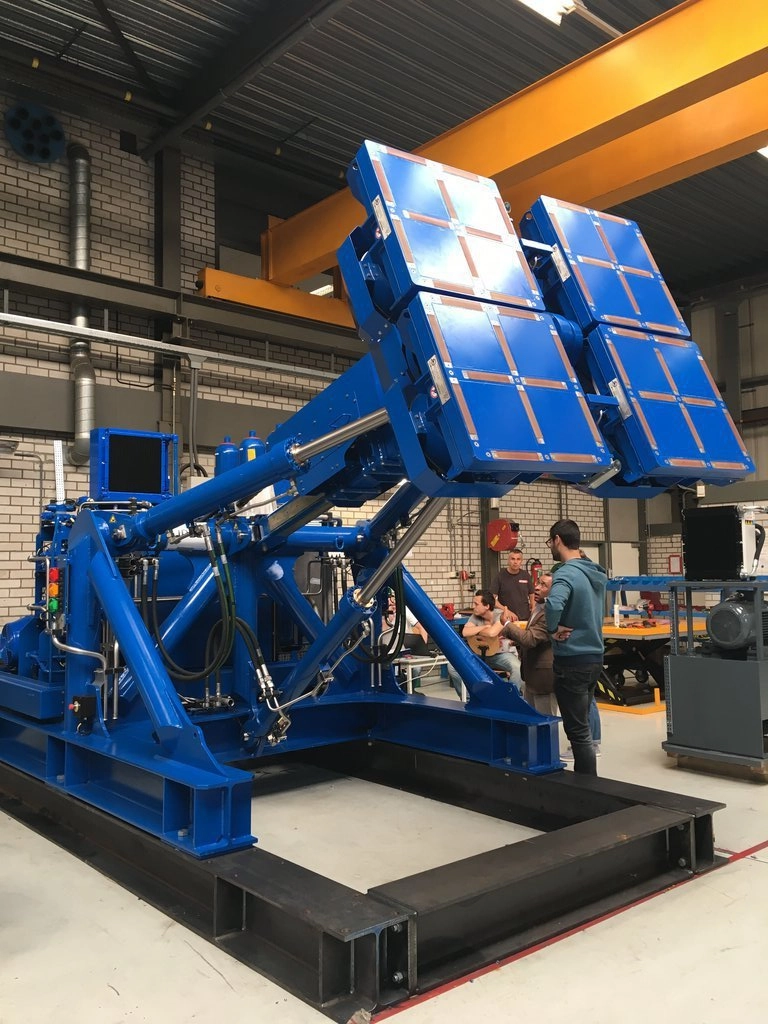

TWD assisted Mampaey Offshore Industries, a market leader of docking and berthing systems, to develop an intelligent DockLocking system (iDL) for automated ship to shore docking. The system is based on a hydraulically operated mechanical arm and electro-magnets.

The Woolwich Ferry, which crosses the river Thames six times per hour, now uses the iDL system when docking. Using a smart method engineering approach, TWD engineers successfully designed the mechanical arm to match the required range of motions and forces for this application.

The design included the support frame, which connects all moving parts to the pontoon, the telescoping element which supports the magnetic pads via the hydraulic cylinders and the support of the magnetic pads, which connects the ferry with the pontoon.

Project highlights

- First magnetic mooring system designed by TWD

- Emission reduction due to the cutting of diesel engines after docking

Constructing something in the marine civil environment? Our fit-for-purpose temporary works help you overcome complex project challenges. Download our track record to explore how we’ve contributed to industry-leading success in projects, featuring clients like VolkerStevin UK, BAM, SRGB, and more