Jacket Seafastening – Borkum Riffgrund

An innovative structure for the future suction bucket jacket seafastenings

For the test suction bucket jacket of Borkum Riffgrund I, Ørsted (Dong), and DEME required a seafastening solution. This seafastening would serve as a solid example for future suction bucket jacket seafastening operations.

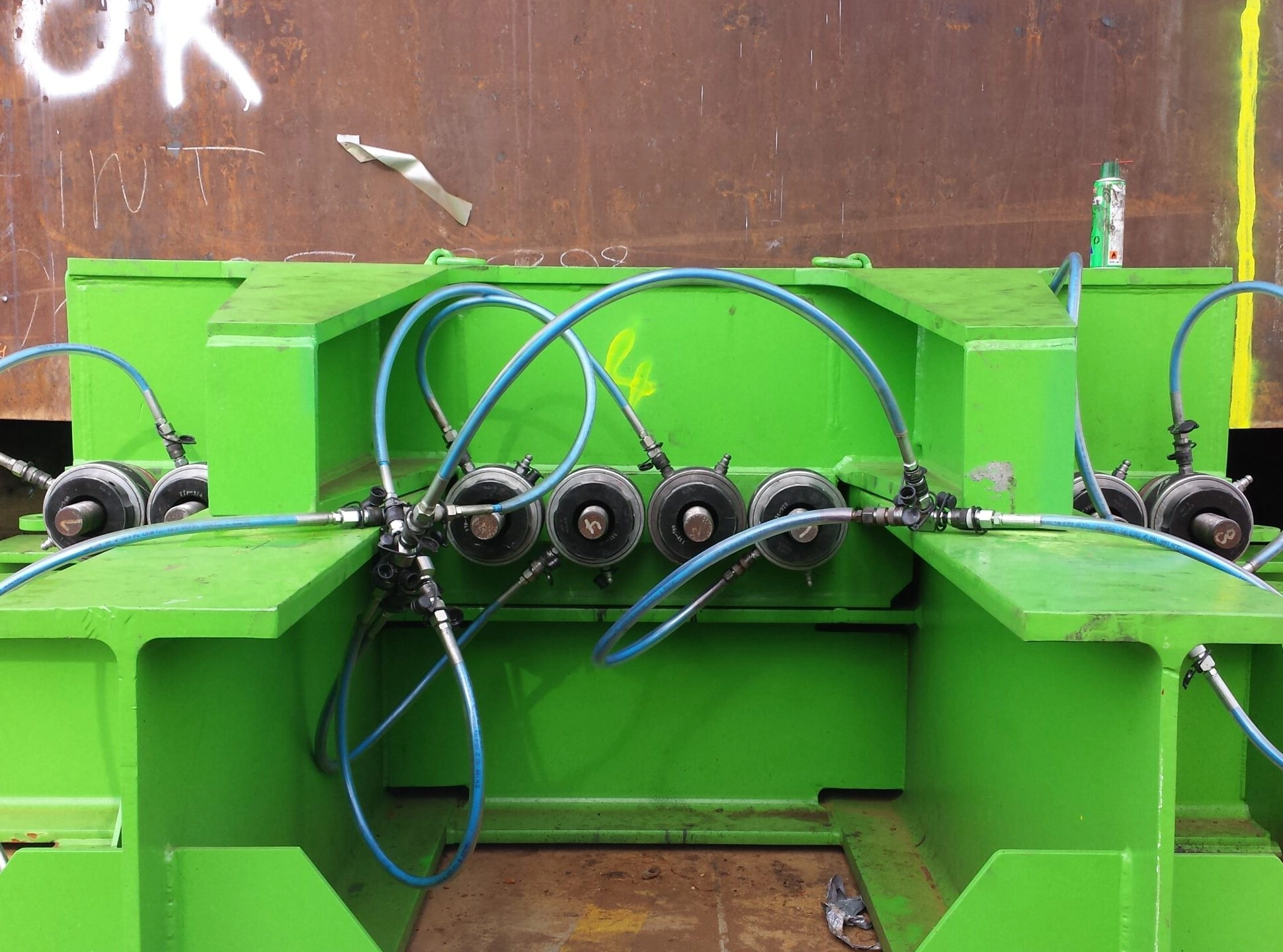

TWD designed an innovative and operation-friendly structure that claps the suction buckets to the deck. The relatively thin buckets were clamped by utilizing pre-tensioned threaded bars to avoid welding or difficult accessible lashing. To prevent the buckets from getting damaged, the clamps were outfitted with a wooden interface. This seafastening structure has brought many tangible benefits, resulting in a more efficient and cheaper installation process.

Our close partnership with DEME and Ørsted (Dong) successfully installed the Borkum Riffgrund wind farm (277 MW) that currently supplies green energy to 320.000 homes per year.

Project highlights

- A solid seafastening example for future suction bucket jacket seafastening operations

- Solution for repetitive suction bucket jacket installations

- Reduces offshore cycle time

- Results in reduced installation costs

As the global wind energy sector expands, a shortage of vessels for handling bigger monopiles is foreseen. Simply scaling up isn’t enough. Download our Whitepaper to explore how TWD tackles supply chain bottlenecks with innovative installation methods, or get our Offshore Wind Track Record to see how we have helped industry leaders succeed in their installations.