Innovation – Monopile Sling Connector

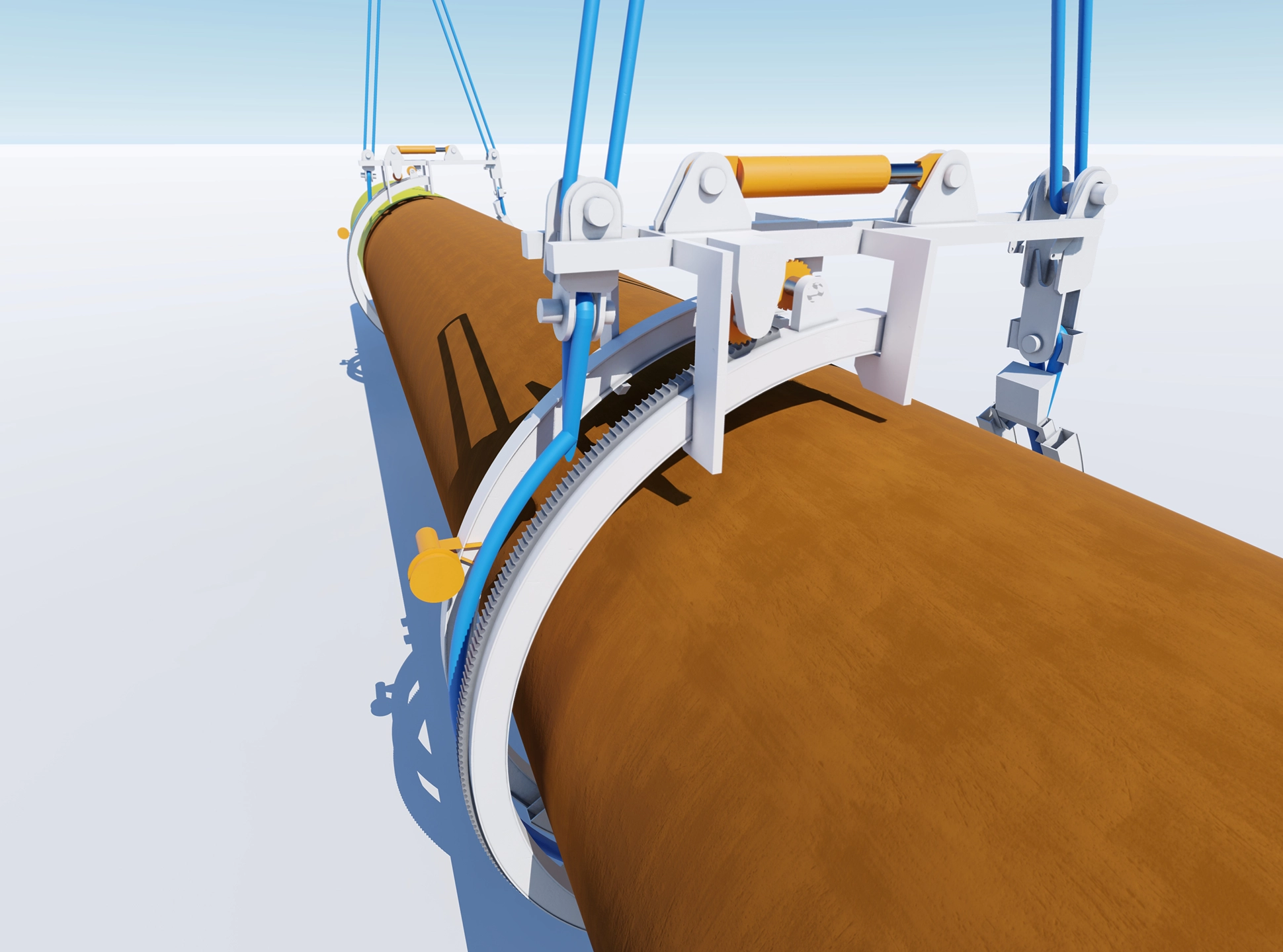

Remote-controlled solution for applying the rigging of monopiles

Transport and installation of monopiles are becoming more and more challenging because of the increasing monopile weight and dimensions. Therefore, to lift larger and heavier monopiles, substantial slings are necessary. Attaching these heavy slings requires manual labor and can be a challenging and time-consuming job. That is why TWD has introduced an innovative concept for the monopile sling connector.

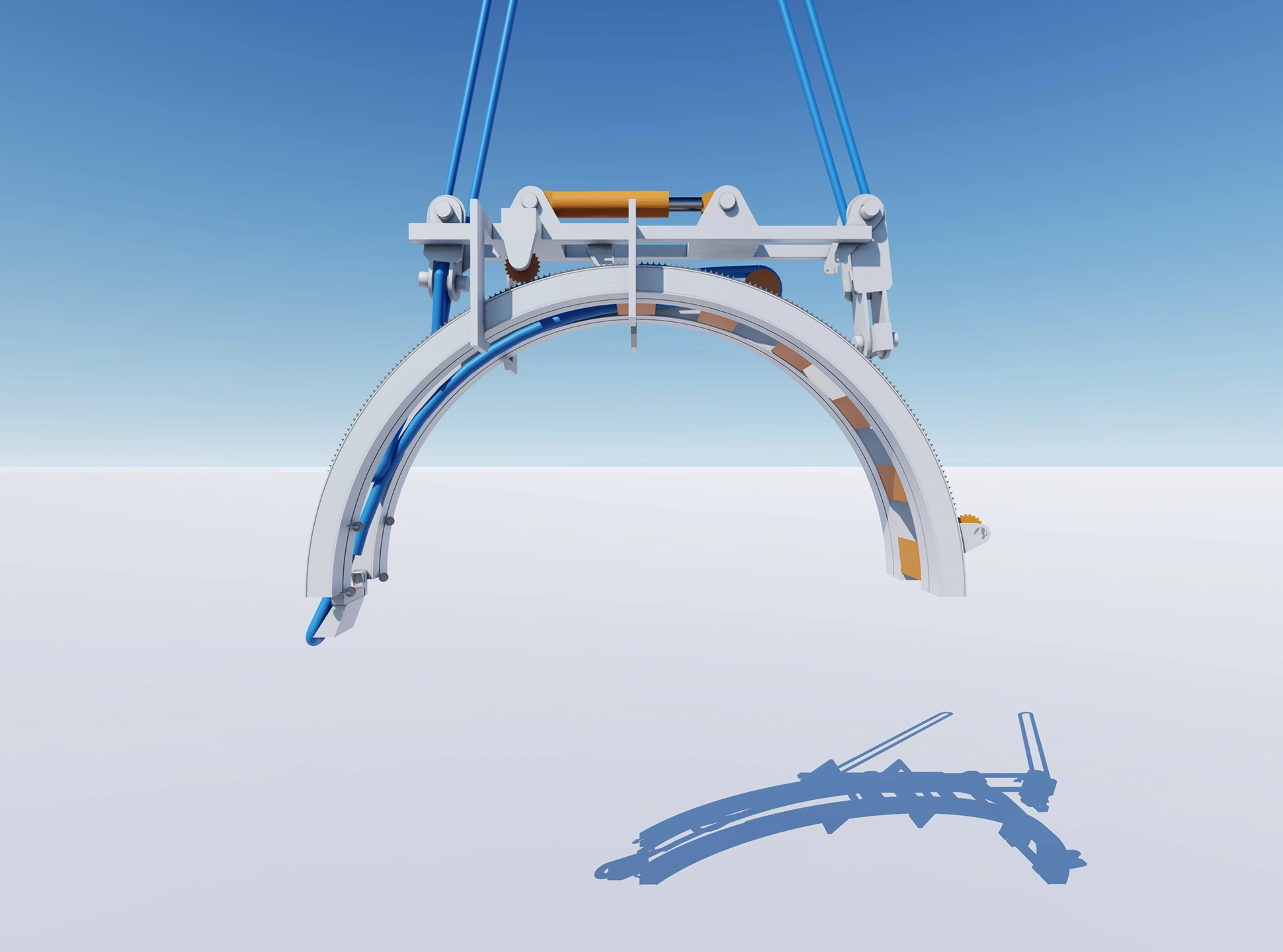

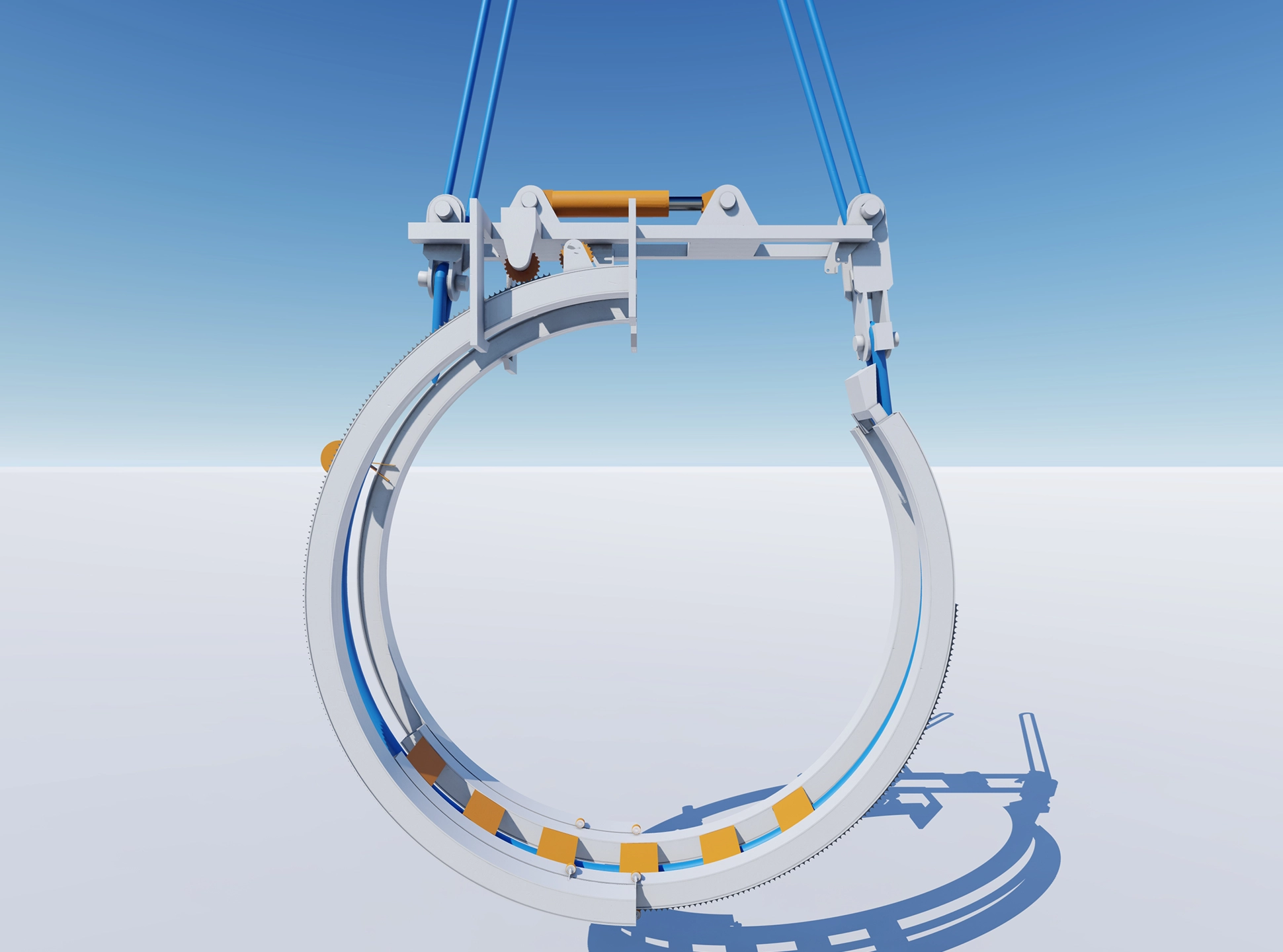

We have designed a quick, safe, and remote-controlled solution to apply the rigging of monopiles. The monopile sling connector allows for applying the rigging on monopiles with various dimensions and in locations with difficult accessibility. Once positioned on the monopile, the sling connector guides the sling around the monopile without the need for human interference. During lifting, the load is transferred directly from the sling, through link plates, to the rigging. In between lifts or during transport, the monopile sling connector can be seafastened on either the deck or the monopile itself.

Project highlights

- The sling connector is remotely operated and excludes manual labor

- Speeds up the rigging operation

- Based on proven technology

- Allows for safe rigging attachment on jack-ups and floating installation vessels

- The sling connector is diameter-adjustable

As the global wind energy sector expands, a shortage of vessels for handling bigger monopiles is foreseen. Simply scaling up isn’t enough. Download our Whitepaper to explore how TWD tackles supply chain bottlenecks with innovative installation methods, or get our Offshore Wind Track Record to see how we have helped industry leaders succeed in their installations.