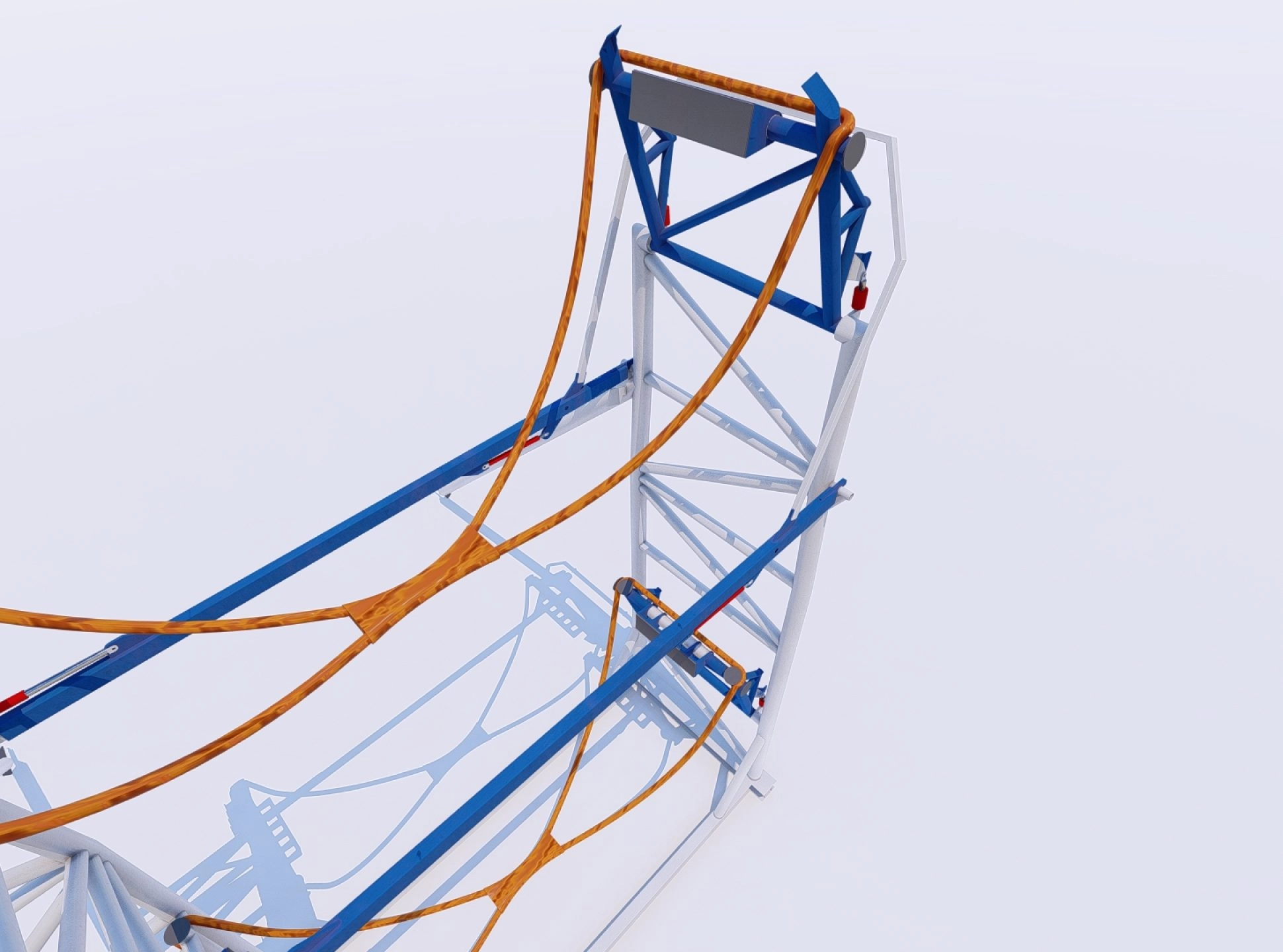

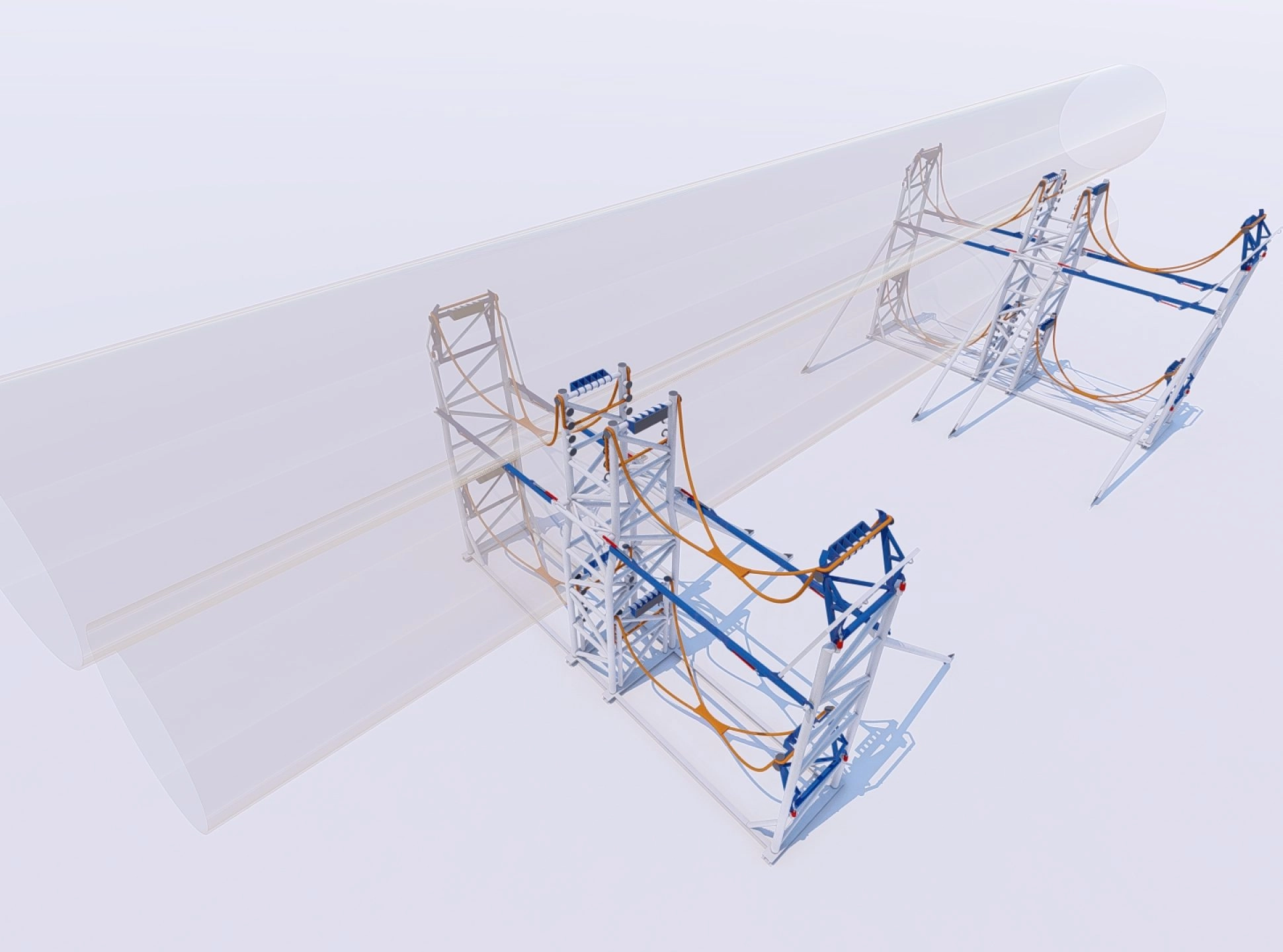

Innovation – Hammock Seafastening

Monopile transportation with the hammock design

Due to different water depths, ground conditions, and turbine sizes, monopile dimensions per wind farm vary greatly. To accommodate these differences, multiple solutions are required. These can include complicated seafastening modifications, or even entirely newly fabricated seafastening structures. These structures largely drive the costs of a transport or installation project. Apart from adjusting to the diameter of the pile, a seafastening should also assure its integrity. With the ever-increasing diameter/wall-thickness ratio, a monopile becomes increasingly delicate to handle. That is why TWD developed The Hammock seafastening to cover both the monopiles currently being installed and the XL monopiles planned for the future wind farms.

The Hammock seafastening solution can be applied on both installation and heavy cargo transport vessels. It is now possible for you to efficiently transport monopile foundations of different diameters without having to change the seafastening spread. When the monopile is hoisted into the seafastening, the weight causes the frame to lock, securely holding the pile. Through supporting the monopile continuously, the monopile integrity remains intact. In addition, we tailor our design to suit your specific requirements and boundary conditions, where a trade-off is made between workability, adjustability, and integrity.

Project highlights

- Hammock seafastening can handle monopile diameters ranging from 7 to 11 meters

- Unique in flexibility; one-size-fits-all

- Beneficial for monopile integrity

- Great benefits for installation and transport contractors – saving investment costs and time

- The hammock is scalable and future-proof

- Robust and efficient structure due to optimal force lines

As the global wind energy sector expands, a shortage of vessels for handling bigger monopiles is foreseen. Simply scaling up isn’t enough. Download our Whitepaper to explore how TWD tackles supply chain bottlenecks with innovative installation methods, or get our Offshore Wind Track Record to see how we have helped industry leaders succeed in their installations.