Foundation Installation Equipment – Galloper

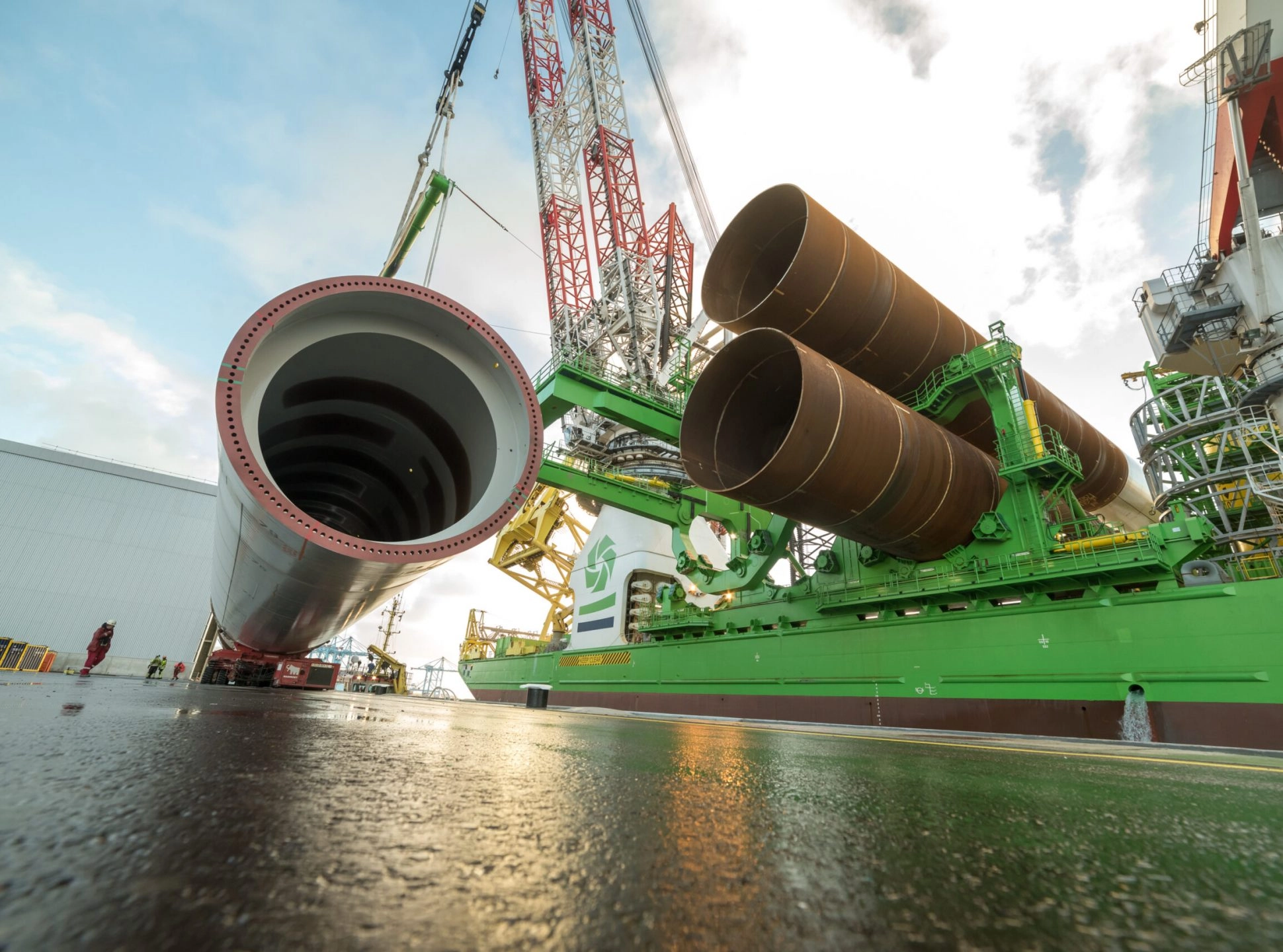

Transport and installation equipment for monopile foundation

Offshore wind turbines and their foundations are becoming larger and larger. This leads to contractors across the industry facing growing challenges because of their vessels’ increasingly limited capacities. To keep their current fleets efficient, innovative engineering solutions are vitally important. An example of these solutions is the upgrade of DEME’s heavy-lift jack-up vessel, Innovation. TWD engineers designed the first-ever skidding monopile seafastening on an installation vessel to handle the large foundations of the Galloper offshore wind farm. Together with the upend bucket and pile gripper, an integrated and future-proof monopile installation spread was realized. Our designs contributed to the smooth installation of the Galloper OWF (353 MW) that powers 380.000 houses with green electricity every year.

Next to the Galloper offshore wind farm, the monopile installation spread was also used on the following farms: Merkur, Rentel, Horns rev 3, Merkur, Hornsea 1, Seamade, Borssele, and Hornsea 2. We made small adjustments to accommodate each farm’s requirements.

Project highlights

- Robust upending tool to safely upend the monopiles

- Rotating saddles to adjust seafastening for multiple pile diameters

- Monopiles on a skid, to bring heavy monopiles closer to the crane

- Two bull-rails, strengthening the vessel’s deck

- Two-layered cradle to load up to 4 piles and reduce the number of installation trips required

As the global wind energy sector expands, a shortage of vessels for handling bigger monopiles is foreseen. Simply scaling up isn’t enough. Download our Whitepaper to explore how TWD tackles supply chain bottlenecks with innovative installation methods, or get our Offshore Wind Track Record to see how we have helped industry leaders succeed in their installations.