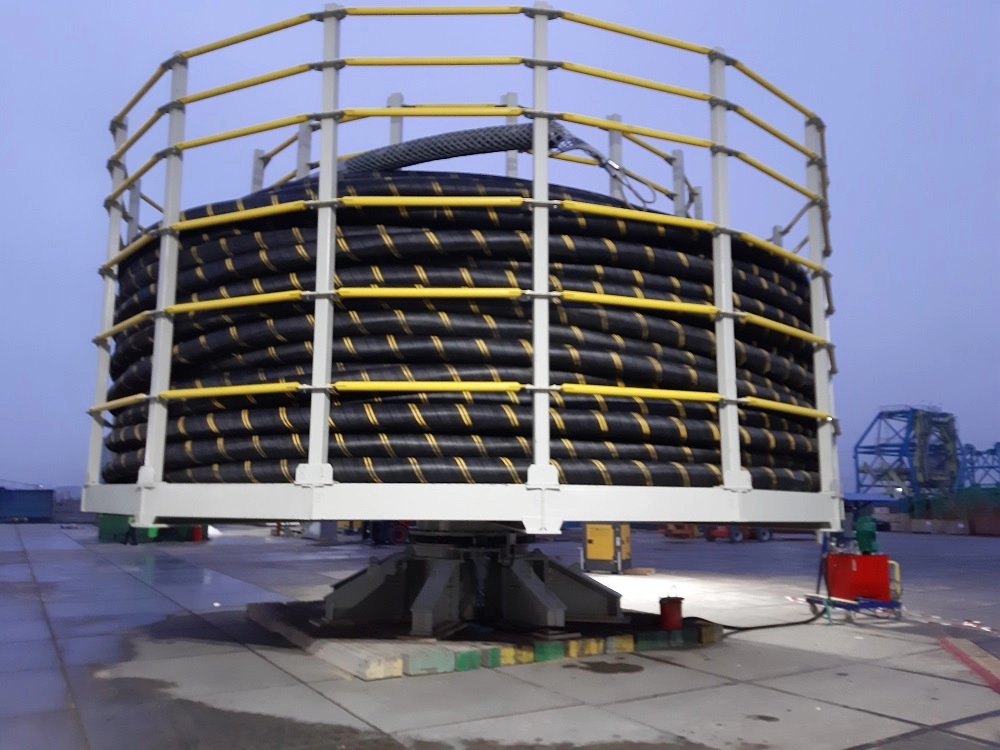

Cable Carousel – Seamade OWF

Export cable – spare part storage carousel

Fulgor SA planned to use an export power cable for the offshore installation on Seamade OWF (487 MW, generating energy for 485.000 households). After the installation, the cable-laying vessel would return to the port while carrying a part of spare cable of approximately 2000m / 200t. Fulgor SA came to us looking for a way to store the spare cable safely. We helped with the design of the onshore cable carousel together with the load-out procedure and the required secondary equipment.

Our teams designed a storage carousel that could be easily disassembled to pieces to enable road transport. Our design included the slewing ring and the hydraulic motor used to rotate the carousel during load-out. Additionally, the carousel dimensions allowed it to be picked up by SPMTs and laid down on permanent support blocks at the storage area. We were proud to see the functionalities of our design lead to fast and safe storage of the cable.

Project highlights

- Design of modular carousel, bolted interfaces enable a breakdown to road transportable items

- Design of load-out procedure, including secondary equipment specification

- Design of slewing ring, motor, gearbox assembly for carousel rotation

- Carousel transportable by SPMTs

As the global wind energy sector expands, a shortage of vessels for handling bigger monopiles is foreseen. Simply scaling up isn’t enough. Download our Whitepaper to explore how TWD tackles supply chain bottlenecks with innovative installation methods, or get our Offshore Wind Track Record to see how we have helped industry leaders succeed in their installations.