Insight Article

Pros and Cons of Modularization: A Rising Trend in Construction

- 2 May 2024

- Insight Article

In the evolving landscape of construction, modularization is emerging as a compelling alternative to traditional stick-built methods, promising efficiency and scalability. This article dives into the advantages and the obstacles associated with modular construction.

When starting a construction project, one of the very first decisions is whether to use traditional stick-built methods or modern modular approaches. The stick-built approach is the conventional method in construction, but modularization is rapidly gaining traction. While modularization offers significant benefits, it also comes with undeniable challenges.

As the world moves from traditional stick-built methods to modular construction, this article highlights the benefits and challenges of choosing modularization over stick-built construction.

- The Rising Trend of Modular Construction

- Benefits of modularization compared to stick-built construction

- Challenges of modularization compared to stick-built construction

If you want to explore further the advantages and disadvantages of modular construction focusing on overcoming sea transport engineering challenges, download our Guidebook below.

1. The Rising Trend of Modular Construction

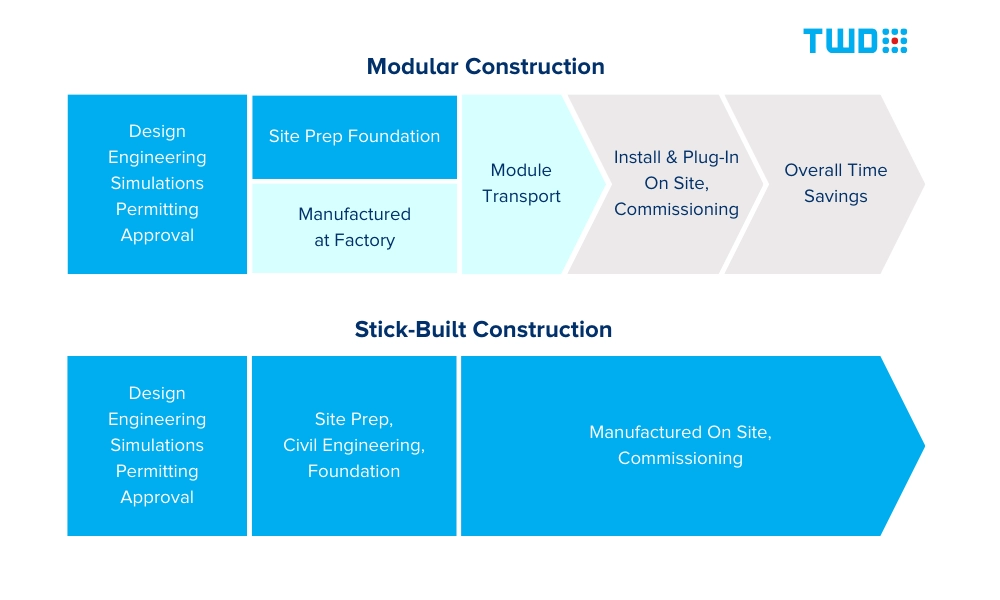

Stick-built vs. Modularized Construction for Plant Design

Stick-built construction is the traditional method where plant components are built and assembled on-site, offering design flexibility but often requiring more time and resources. Each level is erected sequentially, with specific equipment (e.g., boilers) installed at each level before moving to the next.

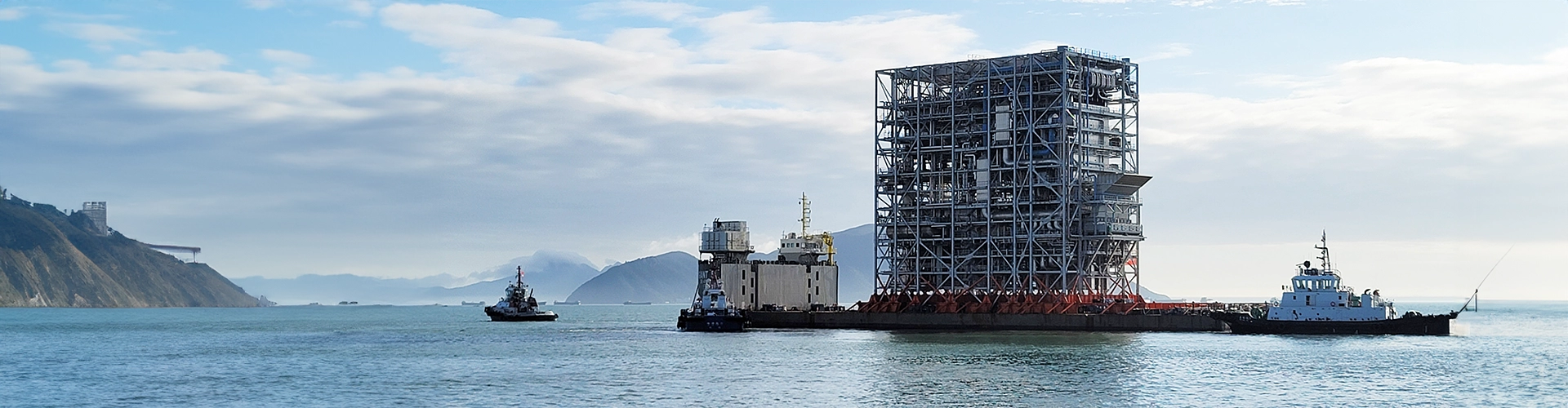

Modular construction involves building parts or entire structures in a controlled fabrication yard away from the site. The plant is divided into sections, each erected separately and pre-fitted with all necessary pipes and bespoke equipment. These modules are then transported to the site for assembly, requiring minor adjustments and connections to be made.

Growing Global Market for Modularization

The global modular construction market is experiencing significant growth. In 2023, the market size was valued at $95.68 billion and is projected to grow to $102.52 billion in 2024, representing a compound annual growth rate (CAGR) of 7.2%. Construction Institute has identified a CAGR of 9.6% until 2027 (Figure 1). This trend reflects the increasing adoption of modular construction methods, driven by their advantages in terms of speed, cost-effectiveness, quality control, and sustainability.

(Source: Getting Ready for 2030: A People, Process, and Technology Roadmap for Offsite Construction)

To determine whether a plant or construction project should be executed using stick-built methods or a modularized approach, a multidisciplinary trade-off analysis is conducted during the early project phases. This analysis, performed as soon as the investment decision is made—sometimes even before—considers all case-specific benefits and challenges.

2. Benefits of Modularization Compared to Stick-built Construction

Firstly, we delve into the key benefits of modularization over stick-built construction. While there are many benefits, we focus on three key areas:

- Enhanced construction process with a fabrication yard

- Improved schedule performance

- Reduction in capital costs

Step-by-step Module Transport Infographic

Are you curious to find out how these benefits can enhance your project? Check out our latest infographic for a comprehensive guide on tackling module transport challenges

2.1 Enhanced Construction Process with a Fabrication Yard

Building sections of a construction in a fabrication yard offers several advantages over building on the final site. Fabrication yards provide a controlled environment for constructing assets, whether it is as big as plant modules or specific equipment. Their location has been strategically selected such that it can accommodate the magnitude of construction, from logistics to capacity.

Location Benefits

- Extended construction windows: Fabrication yards operate year-round, unlike traditional sites that may face weather-related delays, ensuring uninterrupted progress.

- Support for parallel construction: Modularization allows the simultaneous construction of different project segments. While the foundation is being laid on-site, modules for other parts of the project are concurrently being constructed in the fabrication yard. This approach significantly reduces the overall project time and maximizes the utilization of bespoke equipment.

- Efficiency in building and transporting: Building modules on grade and using lift equipment in the fabrication yard improves efficiency and safety. Completed modules pre-fitted with equipment, piping and other assets can be transported to the site, ready for assembly.

Labor Benefits

For companies deciding between stick-built or modular construction, the project’s size is a key factor. Larger projects require more labor. Opting for modular construction and fabricating where labor is readily available can greatly benefit the project. Some specific advantages include:

- Addressing capacity limitations: Modularization reduces the need for on-site labor, helping to manage local labor shortages.

- Elevating skill levels: Workers in a fabrication yard can refine their skills in a controlled environment, resulting in higher quality outcomes.

- Increasing worker productivity: Having workers who are familiar with the environment, the fabrication yard’s safety rules and regulations, as well as the permits and licenses needed to perform specific tasks, can greatly enhance their productivity.

- Enhancing safety: The controlled and predictable environment of a fabrication yard reduces the risk of accidents compared to variable and sometimes hazardous traditional construction sites.

2.2 Improved Schedule Performance

One of the most compelling arguments for modular over stick-built construction is the improvement in schedule performance. Modular projects can be completed faster due to parallel progression of site work and module fabrication.

Compared to a typical stick-built project, which lasts approximately 70 months, modular projects can be completed in around 58 months (source: ‘Modularization’ by M. Kluck & J. Ouk Choi), enhancing return on investment through faster operational start-up.

2.3 Reduction in Capital Costs

Opting for modular construction offers significant savings in capital costs, driven by both direct and indirect factors. Labor productivity, as mentioned earlier, and the all-in wage rate contribute to the overall work-hour cost. According to ‘Modularization’ by M. Kluck & J. Ouk Choi, building in a fabrication yard can be nearly six times cheaper than building on-site. However, in modular construction, additional costs primarily arise from logistics (e.g. land and sea transport).

Beyond these direct cost savings, two indirect factors further enhance cost reduction:

- Efficiency gains: Processes are more efficient in a controlled environment, reducing waste and saving time, which directly translates into cost savings.

- Predictable expenses: The modular approach provides better budget and timing predictability, with fewer unexpected costs compared to traditional construction methods.

Other Benefits

Modularization offers several additional benefits, such as streamlining the erection process and enhancing competitive bidding, especially for module fabrication.

- Streamlining erection process: The erection process faces challenges such as working at heights, dealing with weather conditions, and site restrictions. However, a fabrication yard provides all the necessary provisions to streamline the erection process and maintain a productive and safe working environment.

- Enhancing competitive bidding: Another benefit of modular construction is the opportunity for competitive bidding, based on the large number of module fabrication yards available.

While modularization offers benefits like speed, cost savings, and quality control, it also presents unique challenges that need to be addressed.

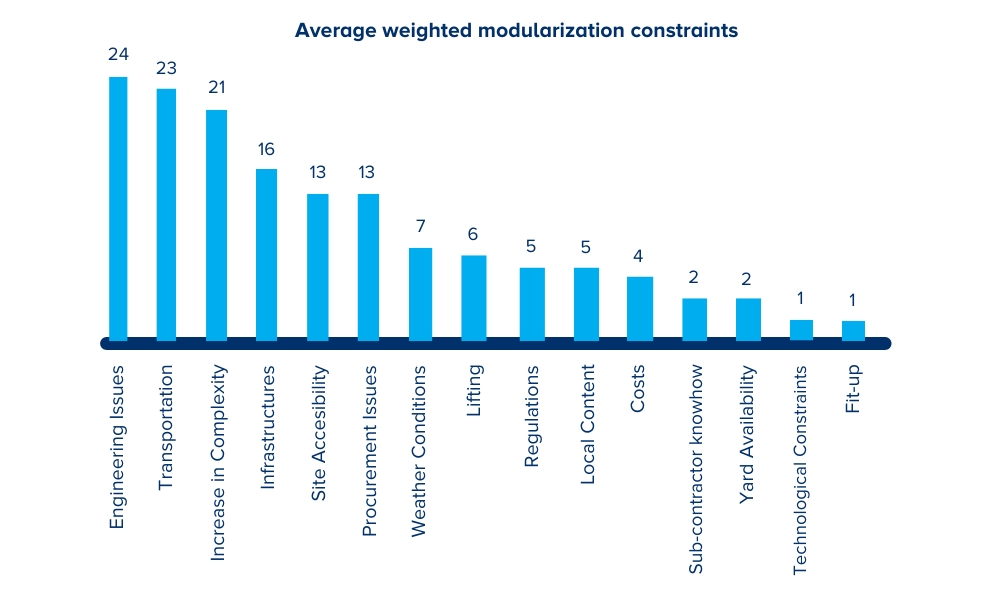

3. Challenges of Modularization Over Stick-built Construction

On the flip side, modularization poses specific challenges that need to be addressed and can potentially become bottlenecks in operations. The following figure (Figure 3) illustrates the average weighted modularization constraints. These findings are based on interviews conducted with EPC managers active in this sector, resulting in concrete findings and valuable insights. The first three constraints are particularly notable, as per M. Mancini in ‘Advances in plant modularization’.

Source: ‘Advances in plant modularization’ by M. Mancini

Engineering Challenges

The engineering issues that come with modularization can pose significant challenges. In a modularized construction, the modules must be engineered with detail before the designs reach the fabrication yard. Since the erection happens in a fabrication yard, parallel activities will be initiated which put strain in the engineering phase due to potential changes in design. Additionally, early-stage engineering often faces uncertainties, leading to a conservative design approach and increased costs.

Transportation of the Modules

The second challenge of modularization is related to transportation, which becomes more complex compared to traditional stick-built methods. In stick-built projects, modules are typically designed for specific conditions like exploitation, earthquakes, and erection. However, with modularization, additional factors come into play, especially when transporting modules over land and sea. This includes considering dynamic effects and accelerations during transport.

Engineers must design temporary reinforcements to ensure module integrity, plan additional methods, identify transport vessels and routes, and make various decisions related to the transport operation. These decisions include considerations for workability, emergency shelters, transport method statements, and temporary transportation equipment such as Self-Propelled Modular Transporters (SPMTs) and ramps to connect the fabrication yard’s quay to the transport vessel.

Increase in Complexity

When adopting a modular approach, the complexity of operations increases. From a project management perspective, dividing construction activities between the site and a fabrication yard results in duplicated planning and supervisory tasks. Both the EPC contractor and the project owner may need to relocate staff to multiple locations, adding to the complexity.

Transport planning is particularly critical. If the delivery time for modules is not estimated correctly, the transport might not be able to wait. This could result in the need to reschedule transport, which may not be available for several months.

TWD’s Module Transport Infographic

With over a decade experience in the Transport and Heavy Lift market, TWD provides independent module transport consultancy to make transport projects easier. Our functional and lean solutions help mitigate risks, reduce costs, and increase project efficiency.

Our latest infographic offers a detailed, step-by-step guide on tackling the challenges associated with module transportation, from selecting cranes and vessels to on-site inspection and mobilization. Download the infographic now to discover how TWD can help enhance your project’s efficiency and reduce costs in your transportation operations.

Explore Our Assets

Are you considering installing a modular power plant? Our specialized mission equipment is tailored to tackle complex project hurdles. Discover how to fully capitalize on marine, method, and structural engineering to optimize your modularization project with our Guidebook or download Track Record to see how we simplified the construction for our clients.

Introduction Meeting

Need tailored advice for your project? Whether it’s engineering, design, or transport-related queries, we’ve got you covered. Schedule a meeting today with our specialist in heavy lift operations to kickstart the success of your heavy lift and transport project.

Share this article on