Understanding Pile Run and How to Mitigate Risks

- 1 August 2024

- Knowledge

Pile run poses significant risks during the construction of offshore wind farms. Whether installing a monopile or jacket pile, a pile run can have severe consequences. Sites in Korea, Japan, and Taiwan have a particularly high risk due to the large variability in soil types over depth. This article delves into the phenomenon of pile run and explores potential mitigations for its negative effects.

What is pile run and what are the consequences?

To grasp the problem, it’s essential to understand what causes pile run. Simply put, a pile experiences soil resistance during the three stages of penetration in the ground: set-down, self-weight penetration, and driving. The resistance of the ground is influenced by the ground conditions, pile tip position, velocity, and weight. Calculating the resistance during all stages of installation plays a crucial role in predicting pile run.

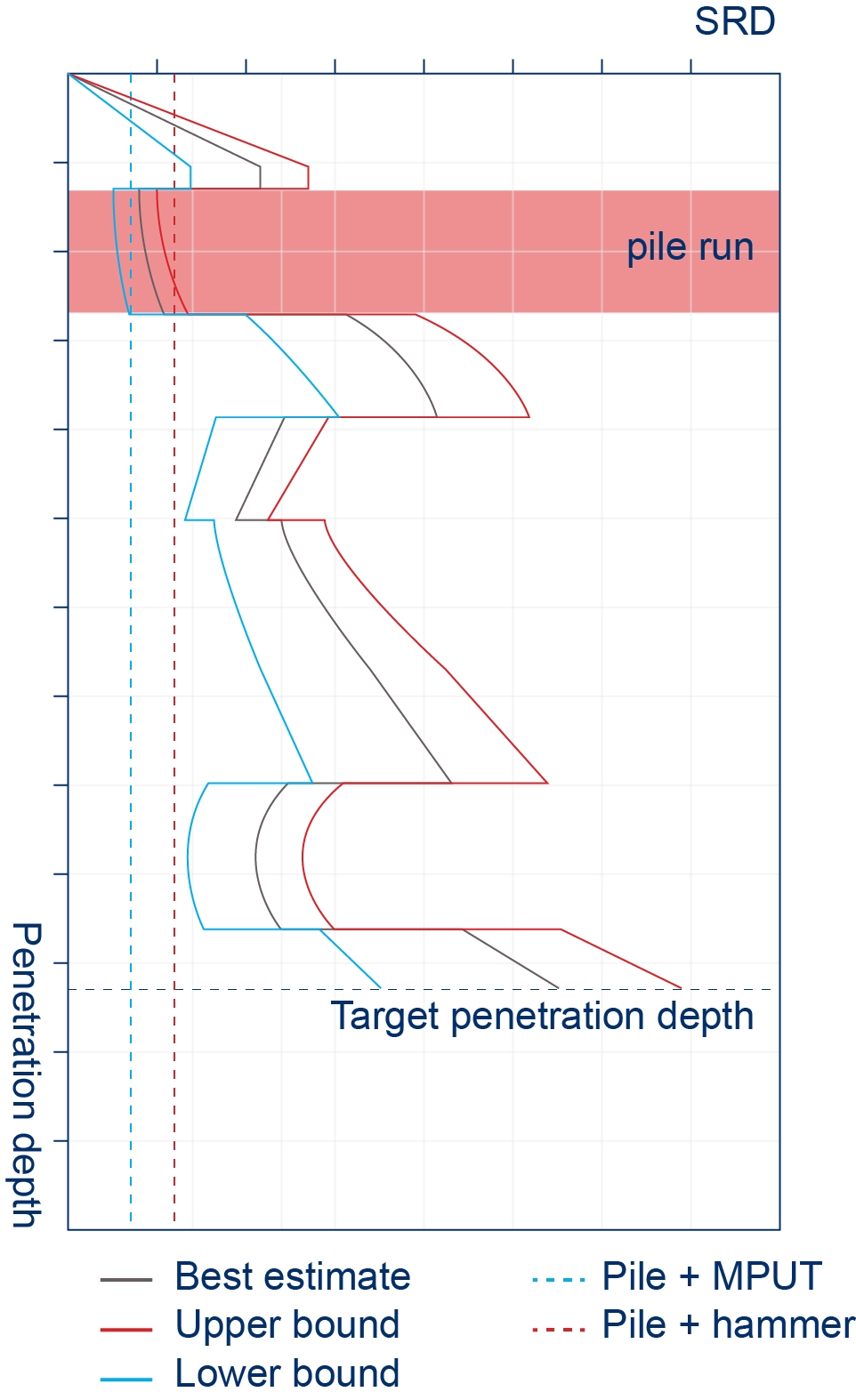

If the weight and inertia of the driving assembly (pile + lifting tool or pile + hammer) exceed the soil resistance, the pile starts to accelerate. This is the start of the pile run. Once the soil resistance during the pile run becomes larger than the weight and inertia of the assembly, the pile begins to decelerate. Once stopped, the pile run event is completed.

For decades, static formulations have been used to predict pile runs. These formulations normally serve as input for drive-ability calculations. In some cases, these formulas allow for the identification of pile run risk, as shown in Figure 1. The vertical lines indicate the static resistance of a monopile with a lifting tool (blue) and with a hammer (red). Once the Static Resistance to Driving (SRD) is lower than these two static weights, there is a pile run risk.

Pile run can result in significant damage in different ways. If a pile run occurs during driving, the hammer weight can cause a sudden increase in hook load. These shock loads can damage the crane, initiate uncontrolled motions of the hammer, and in the case of a floating vessel, cause large roll motions. If a pile run occurs near target depth, the low soil resistance combined with kinematic energy built up could result in a pile penetrating beyond target depth.

Figure 1, Example of SRD chart

In case of predicting a pile run, operational precautions can be taken. Predicting pile run is a complex job as soil-structure interactions are complex, and predicting ground response during pile driving is not merely a geotechnical job but also involves dynamics and operational engineering.

Challenges in predicting pile run?

There is much literature on soil-structure interaction that helps to predict the static resistance of piles. Often the formulations in the literature are based on predictive models for sand and clay (for example, the most used method of Alm & Hamre [1]). These models have shortcomings when applied outside the area they were developed for.

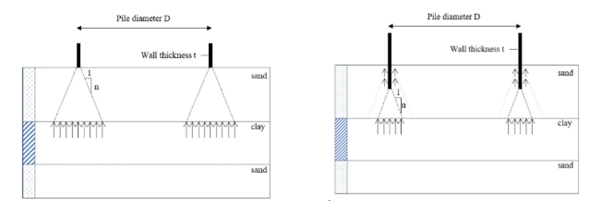

The original Alm and Hamre (1998) model was developed from back-calculated drive-ability studies from North Sea installations. An updated version in 2001 incorporated Cone Penetration Tests (CPT) to address variability and uncertainty in soil parameters. However, CPT data can be scattered, and a large bandwidth of data is often used to create upper and lower bound estimates. This model is based on North Sea data, while offshore wind projects are spreading globally, encountering different soils, influencing the soil resistance during installation and pile run predictions. In addition, the transition between different soil layers is not discrete, while the models are. That is why nowadays, models are applied which take interbedding of soils into account. This is crucial as end-bearing resistance, especially at shallow depth, is influenced by the layers of soil below (see Figure 2).

Figure 2, The influence of soil variability over depth on end-bearing (R. Thijssen [2])

How to manage pile run?

With a basic understanding of pile run and its prediction, we can discuss mitigation strategies. One method is to increase soil resistance by allowing for an increase in end-bearing. This refers to the resistance of the soil provided when the pile tip penetrates further into the soil. Increasing end-bearing is very effective at shallow depths, where it dominates the overall resistance. Conversely, at deeper depths, the increased end-bearing can also hinder driving the pile up to target depth.

Increasing the bearing of the pile can be executed by adding steel plates, rings, or strips to the shaft of the pile. As discussed above, these mitigations can be tailored to specific site conditions, strategically activating resistance at predetermined depths. Existing formulations should be adapted to properly account for these methods, as standard formulas cannot.

Operational decisions also help mitigate pile run’s negative effects. Examples include a shock absorber, using a vibratory hammer, or pre-ballasting the pile. Applying ballast allows controlled penetration of softer layers. However, operational changes affect the cycle time, can be limited by crane capacity, and may impact the design of the permanent works. This is why every site requires an individual evaluation.

To further reduce the risks associated with pile run, utilizing additional specialized equipment can prove to be highly effective. Several innovative solutions can be considered, such as:

Shock load absorbers:

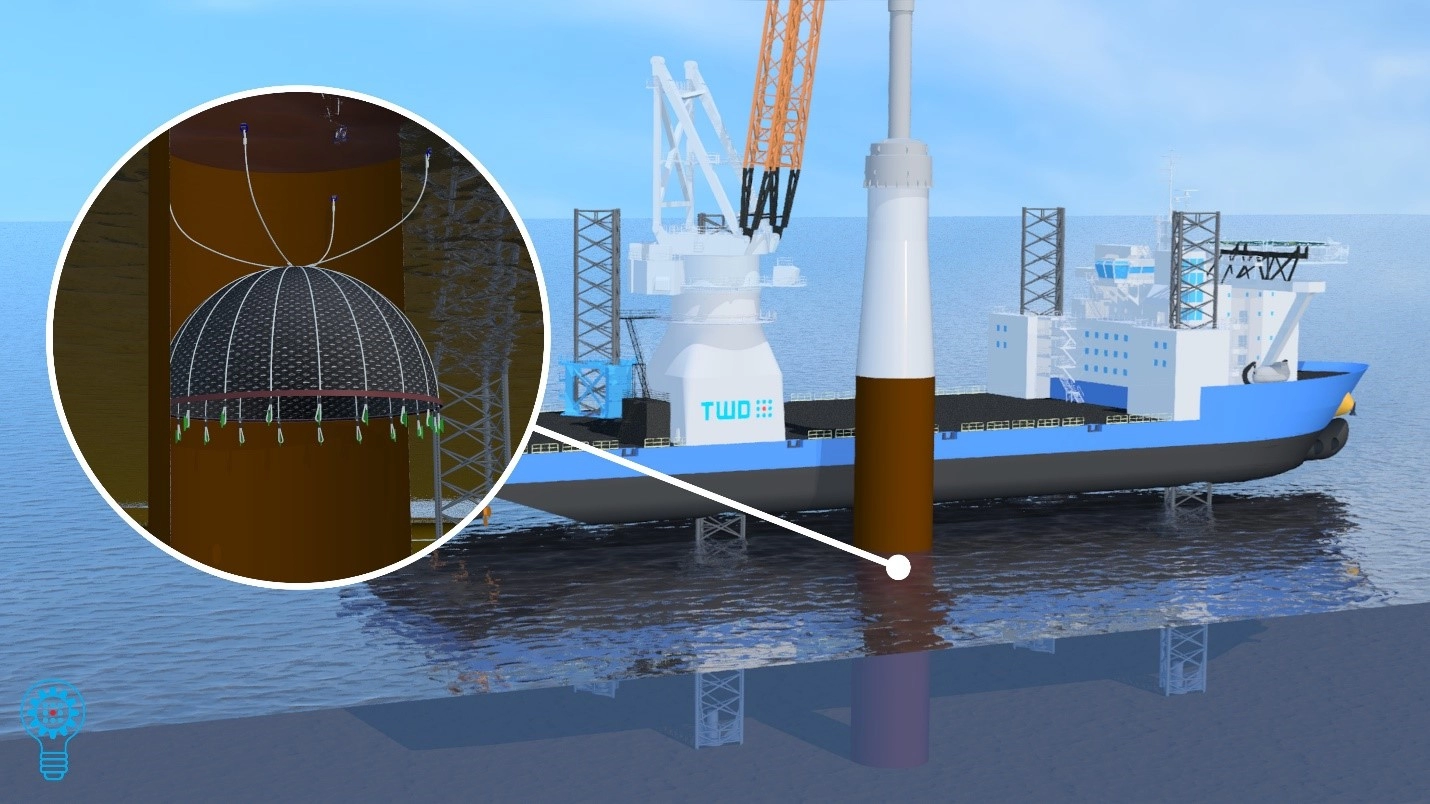

Positioned in the crane rigging, a shock load absorber can soften the sudden snap loads of the hammer falling back into the rigging. This greatly reduces risks of crane and equipment damage. Sometimes, due to limited crane height there are challenges of fitting the shock absorber in the crane rigging, here tailored solutions like TWD’s ‘short stroke shock absorber’ could be adopted in the crane’s traverse.

Figure 3, schock load absorber

Pile run parachute:

Include a flexible parachute inside the monopile, that is in the water as the pile run depth is reached. The water that is encapsulated in the pile, between the parachute and soil, is forced to flow through the parachute as a pile run event occurs. The parachute will thus act as a damper to the system.

Figure 4, Pile run parachute

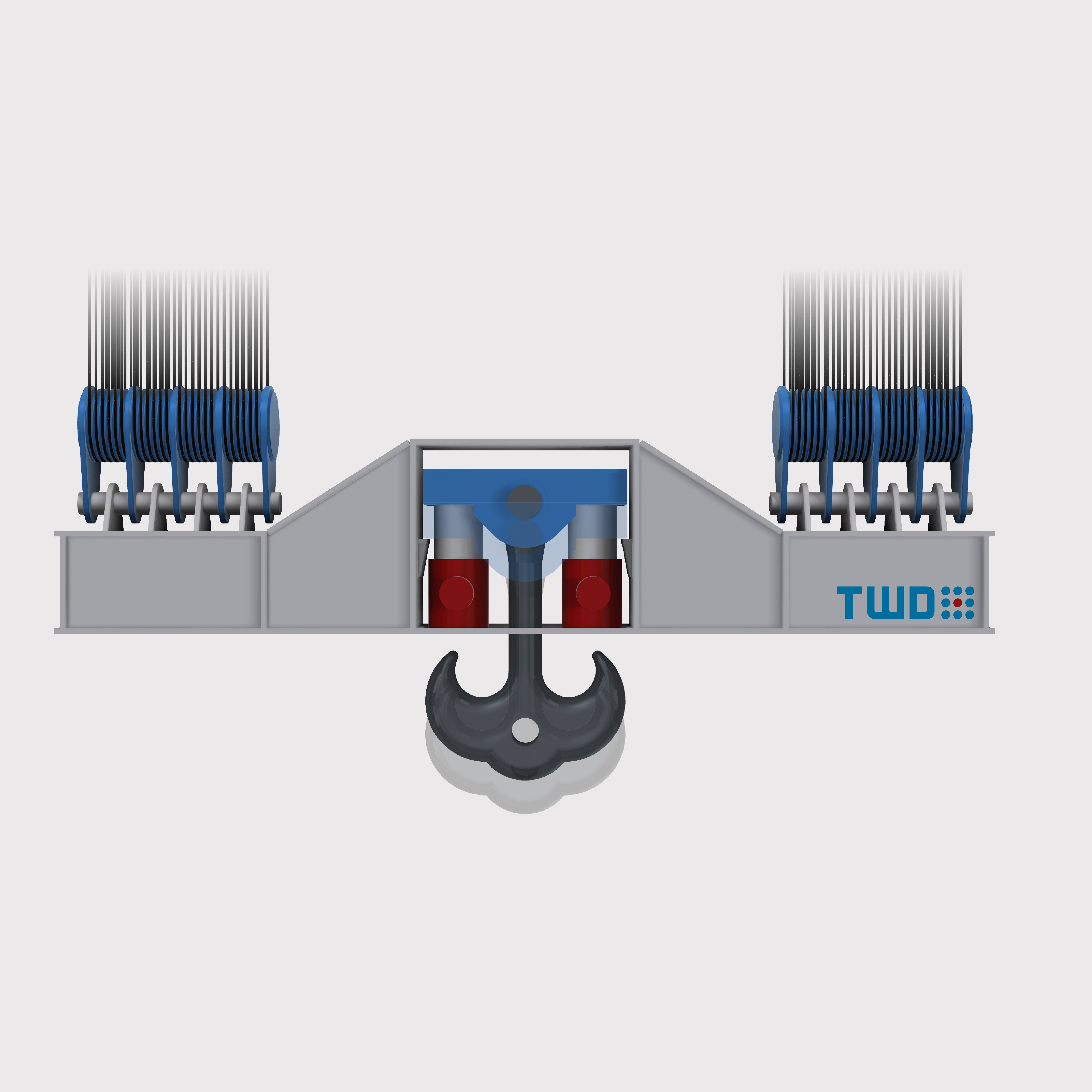

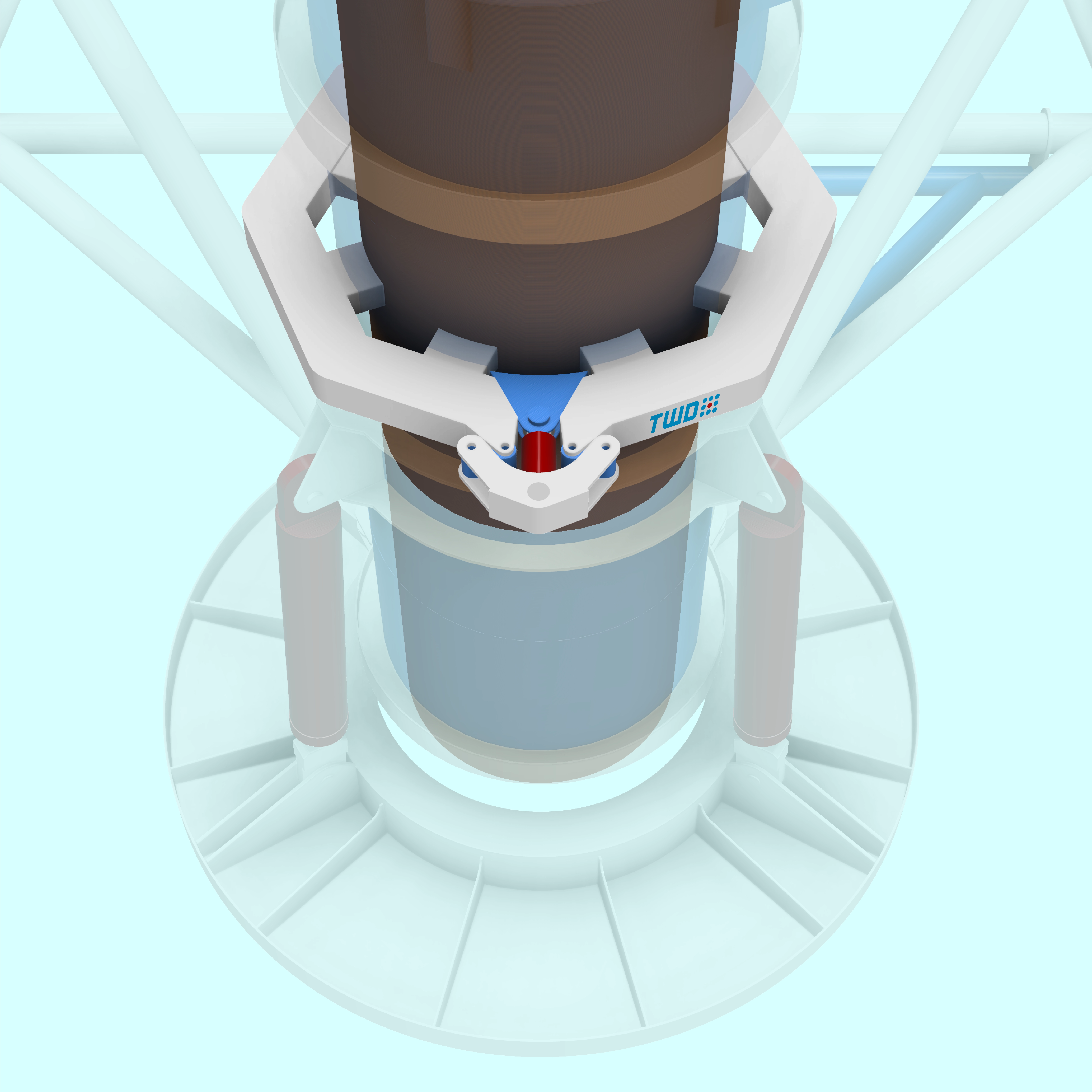

Pile seabed template with emergency brakes:

A seabed template, commonly encountered for pre-piled jackets, can include an emergency brake which is activated as the pile starts to accelerate, causing additional friction with the shaft which will decelerate the pile.

Figure 5, Template pile clamp

A pile cap to create overpressure in the pile:

The weight of the pile on the soil is lowered with the use of buoyancy. This ensures that if the soil resistance is lost, the pile remains in place.

Conclusion

Pile run is a serious issue, for which predictability depends on the availability and accuracy of soil data. Although adjustments can be made to the piles, these rely on the soil-pile interaction, which comes with uncertainty. Operational decisions can be made to deal with the negative effects, but these impact the operation. Additional equipment provides a solution, but most importantly, it is essential to recognize that the optimal pile run solution is project-specific. TWD has experience in determining the origins of pile run events as well as in finding the most suitable mitigation measure for your offshore wind project.

References:

[1] Alm & Hamre – ALM Method – 2001

[2] R. Thijssen – “Risk Mitigation for Punch through of XXL Monopiles – MPM Validation and Field Observation” – 2024

Our in-house Innovation team anticipates market trends and leverages insights to keep our clients ahead. We are dedicated to developing innovative mission equipment. Download the Design Special for Pile Run Parachute below to learn how this innovation mitigates Pile Run risk.

Innovative solutions come in many forms. Our experts collaborate with clients, regulatory bodies, and universities to generate the best ideas. We conduct thorough research, create demonstrators, and organize brainstorming sessions to develop future construction solutions. Schedule a consultation with our specialists to see how we can assist with your next project.

Share this article on