- 2 Jan 2025

- Knowledge

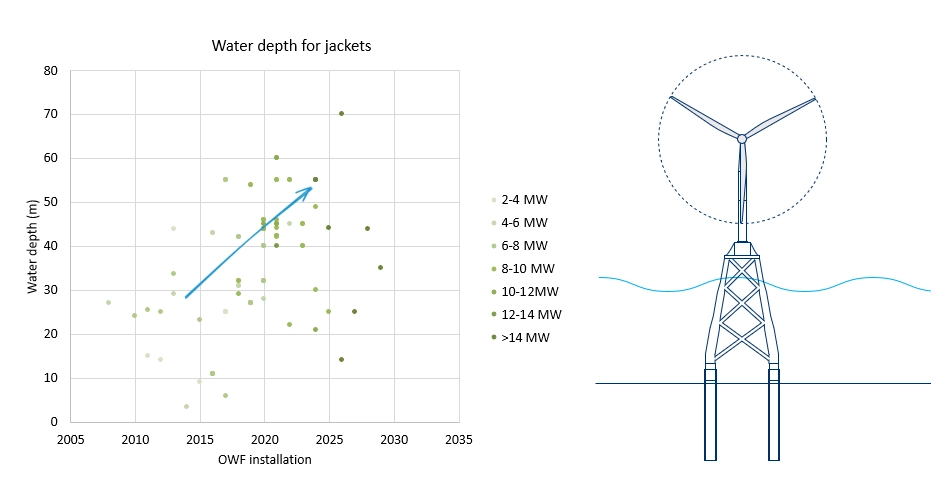

The offshore wind industry has made remarkable progress over the past decade, driven by the need for sustainable energy. A significant part of this progress in fixed-bottom offshore wind projects is the design of pre-piling templates for jacket foundations, ensuring precise alignment and spacing of piles. As turbines grow larger and move into deeper waters, these templates have evolved considerably. In this article we take a closer look at the market trends and challenges related to these changes.

Increasing Size of Jackets and Pin Piles

One of the most notable trends in the offshore wind industry is the steady increase in turbine size, leading to larger jacket foundations. Modern turbines now have rotor diameters over 200 meters and capacities of 15 MW or more. This growth is driven by the need to maximize energy production and improve the cost-efficiency of wind farms. An example of this continuing trend is the MySE 18.X-28X turbine by Mingyang Smart Energy that is now being tested on land, which boasts a 280 meter rotor diameter and a rated capacity of 18 MW.

Traditionally, fixed-bottom turbines have been installed in waters up to 60 meters deep. However, the trend toward deeper water installations, combined with the growing size of turbines, has led to an increase in foundation size. As turbines and jacket foundations grow, so do the pin piles used to anchor them.

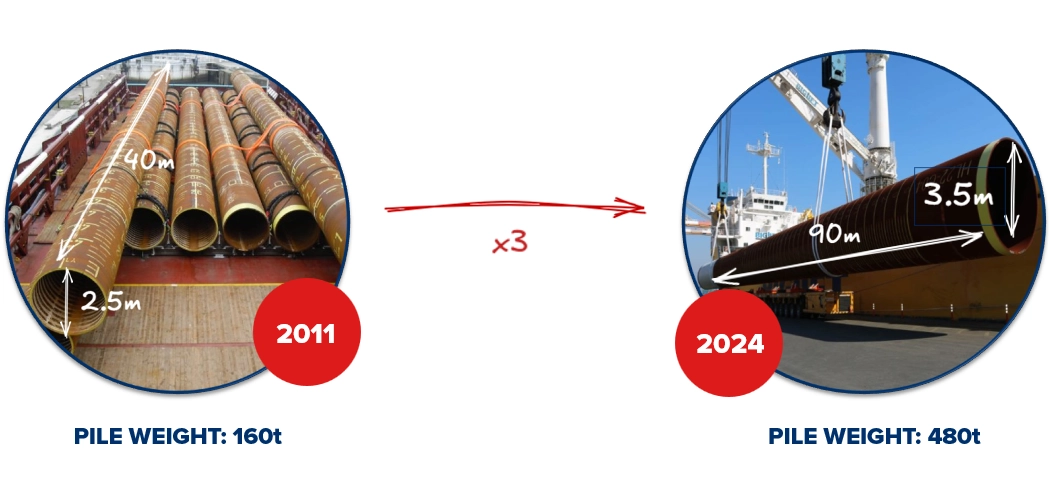

A decade ago, pin piles were typically around 40 meters long, 2.5 meters in diameter, and weighed about 160 tonnes. Nowadays, these dimensions have increased a lot, with pin piles reaching lengths of up to 90 meters, diameters of 3.5 meters, and weights of around 500 tonnes. This increase in size is needed to provide the stability required for larger turbines and deeper water installations.

Engineering Challenges in Scaling Up Pre-Piling Templates

Accommodating these larger pin piles leads to larger pre-piling templates. Designing templates that can handle the increased forces and environmental conditions is a big engineering challenge. Here are the five key issues engineers face, especially for jacket foundations:

- Structural integrity: As offshore wind turbines grow larger and installations venture into harsher marine environments, pre-piling templates face increasingly demanding conditions. The structural integrity of these templates becomes a critical concern, as they must withstand greater forces exerted by both the larger foundations and the environment. These forces include dynamic loads from waves and currents on the piles and loads from the hammering activities.

- Accurate placement: Larger templates must maintain precise alignment and stability during installation. For instance, a 90-meter pin pile weighing 500 tonnes must be placed with millimeter precision to ensure structural integrity. This is challenging due to the increased weight and size, which can lead to greater susceptibility to environmental forces such as waves and currents. Engineers must design templates that can self-level and adjust to seabed contours to ensure accurate pile placement.

- Soil-structure interaction: The interaction between the template and the seabed becomes more complex with larger and heavier structures. Engineers need to account for challenging and exotic soil conditions and ensure that the template is designed to handle the project specific seabed characteristics. The availability of reliable data on seabed and soil is essential. This includes geophysical and geotechnical data obtained through seismic surveys, cone penetration tests and analysis of boring samples.

- Manufacturing and mobilization: Producing larger templates involves more complex manufacturing processes and requires specialized facilities. The assembly of these templates on-site also poses logistical challenges, as they need to be transported and assembled using heavy-lift vessels and equipment.

- Cost-efficiency: Scaling up templates increases costs, both in terms of equipment costs and the complexity of the installation process. Projects must balance, equipment cost, workability and installation speed to keep costs manageable

Join TWD’s webinar Future of Jacket Installation

As the offshore wind industry continues to push boundaries, the engineering and logistical challenges become more complex, highlighting the importance of a holistic project approach and innovative engineering solutions. TWD can assist with offshore engineering projects by providing expertise in equipment design and method engineering. Our multi-disciplinary teams can help develop tailored solutions to meet the specific needs of your project.

For more information, download TWD’s jacket foundation track record, which showcases our experience and successful projects in jacket foundation installation worldwide. Additionally, we invite you to join our webinar “Future of Jacket Installation” on February 5th where we discuss the challenges and innovations for jacket foundation installation, focusing on the Asian Pacific region. This webinar will provide valuable insights and allow you to engage with industry experts.

Share this article on