New whitepaper: Buoyancy Assisted Monopile Installation

- 21 October 2024

- News

The global offshore wind industry is experiencing rapid growth, driven by the need for renewable energy in regions like Europe, Asia, and North America. This expansion, fueled by the ambitious targets set by the Paris Agreement, demands the development of larger wind farms in deeper waters with more challenging soil conditions. As a result, wind turbines are increasing in size, and their monopile foundations are becoming heavier and more difficult to install.

Traditional crane-based installation methods struggle to keep up with these demands, as the weight of modern monopiles exceeds the capacity of many heavy-lift vessels. Hence there is a problem of supply chain bottleneck, posing a significant threat to the continued growth of offshore wind projects, crucial for meeting global energy goals.

Innovative Solutions

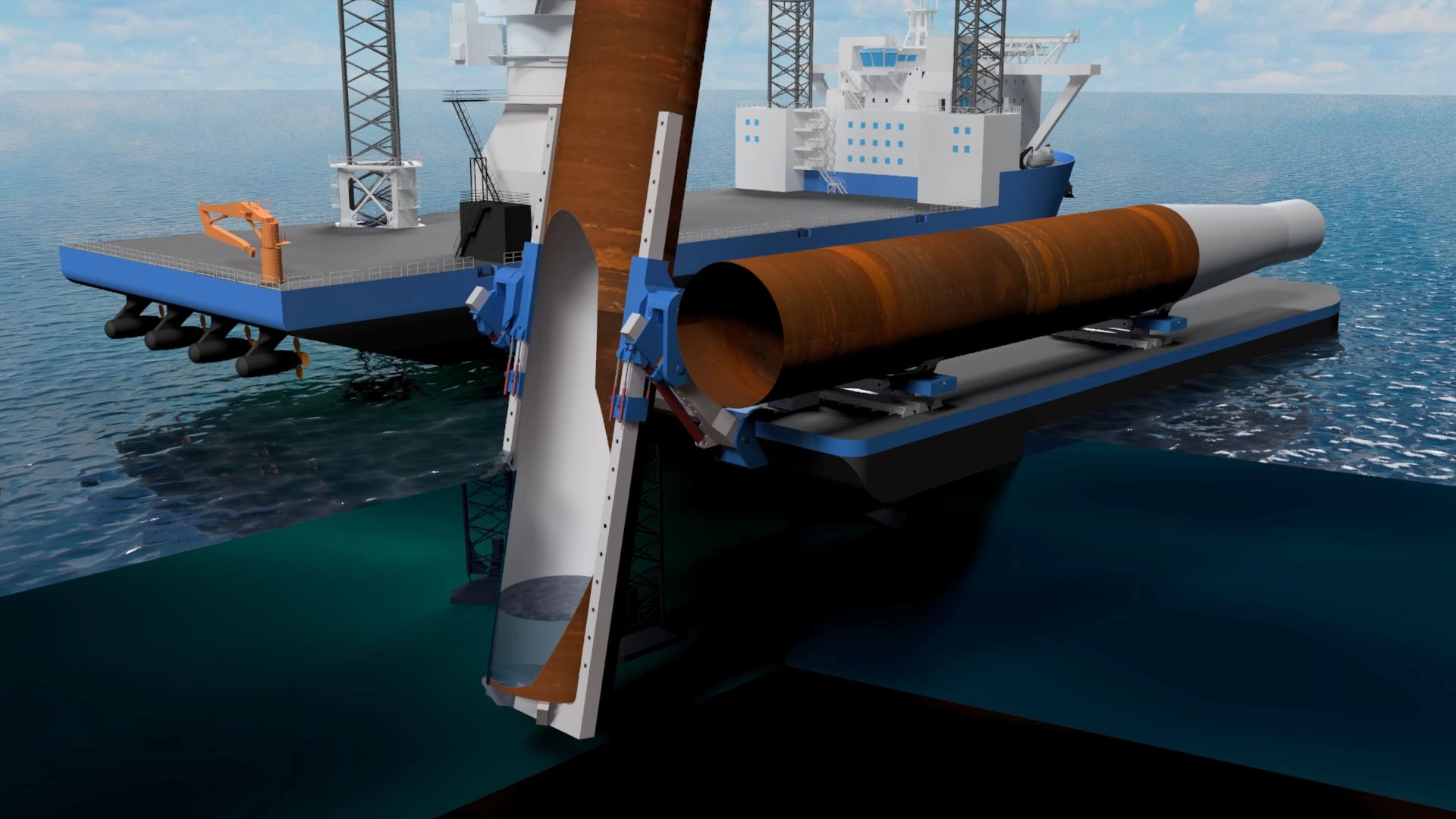

In response to these challenges, a newly published TWD white paper Buoyancy-Assisted Monopile Installation (BAI) presents innovative solutions. The paper explores how buoyancy-based methods can reduce dependency on cranes during installation. By utilizing the natural buoyancy of sealed and/or pressurized monopiles, BAI technology generates an upward force that assists in lifting, lowering, and installing the monopiles. This approach lowers the external lifting load required, opening up the possibility for more vessels to be used in the installation, increasing efficiency, and reducing costs.

The white paper details three key methods:

- Upend hinge installation

- Floating monopile installation

- Craneless installation

Each of these methods is backed by case studies that demonstrate their potential in various offshore conditions.

Fostering the Growth Targets

By advancing these buoyancy-assisted techniques, the white paper provides a roadmap for overcoming the limitations of current installation technologies, offering a scalable solution to the growing demands of the offshore wind industry. It’s important to note that these complex solutions must be customized according to the specific project factors to utilize their potential fully without compromising the efficiency and safety of the installation process. Collaboration and further development are encouraged to implement these innovations, which could fundamentally transform monopile installation and support the industry’s ambitious growth targets.

Method Engineering by TWD

By evaluating and forming the optimal construction method at an early stage, our Method Engineering service helps you complete successful projects. Our team of multidisciplinary engineers understands that smart transport and installation methods can bring competitive tenders and profitable projects. That is why we approach every challenge with method engineering – a process that develops the optimal construction sequence, defines required assets, and specifies the needed temporary works when the project starts, ensuring its safe, timely, and cost-effective completion.

Curious to know how Method Engineering can benefit your next engineering project? Reach out to learn more.

Share this article on