News

Monopile Integrity Experts

- 03 September 2020

- News

Today’s monopile is a radically different foundation than it ever was.

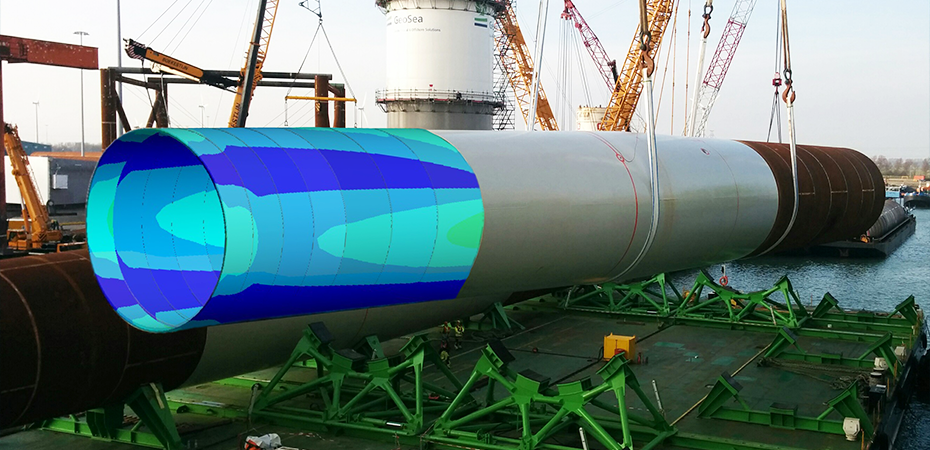

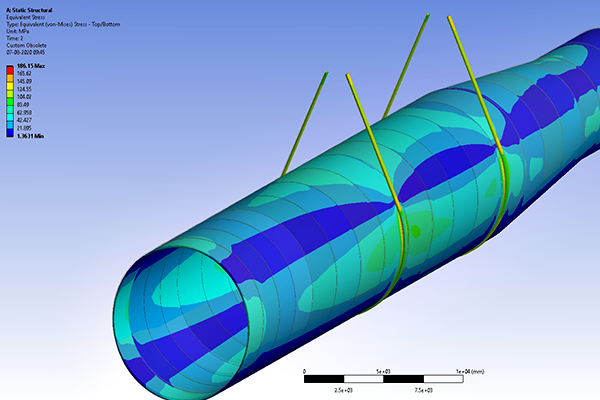

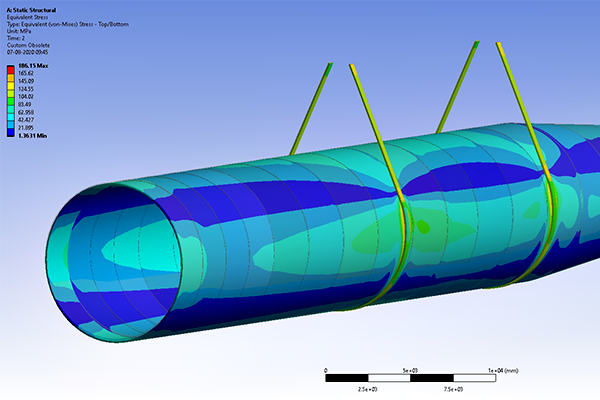

Monopile diameters, weight, and length increase while at the same time farm locations are more remote which causes increased environmental loads as well as sailing time. MP dimensions vary within one windfarm while ever-increasing innovation in foundation design results in smaller can thicknesses. All these effects cause transport and installation to be a critical load case to check for the structural integrity of each monopile.

TWD is able to rapidly verify the integrity of your foundation from fabrication up to the end of installation:

- Loadout

- Storage

- Lifting

- Transatlantic transport (fatigue)

- Transit to the installation site

- Upending

- Installation

Questions?

We would be happy to organize a (digital) meeting with you and our Monopile Experts to think along with any challenges you might have and discuss the benefits of our analyses on the operation. Get in touch with us today.

Share this article on