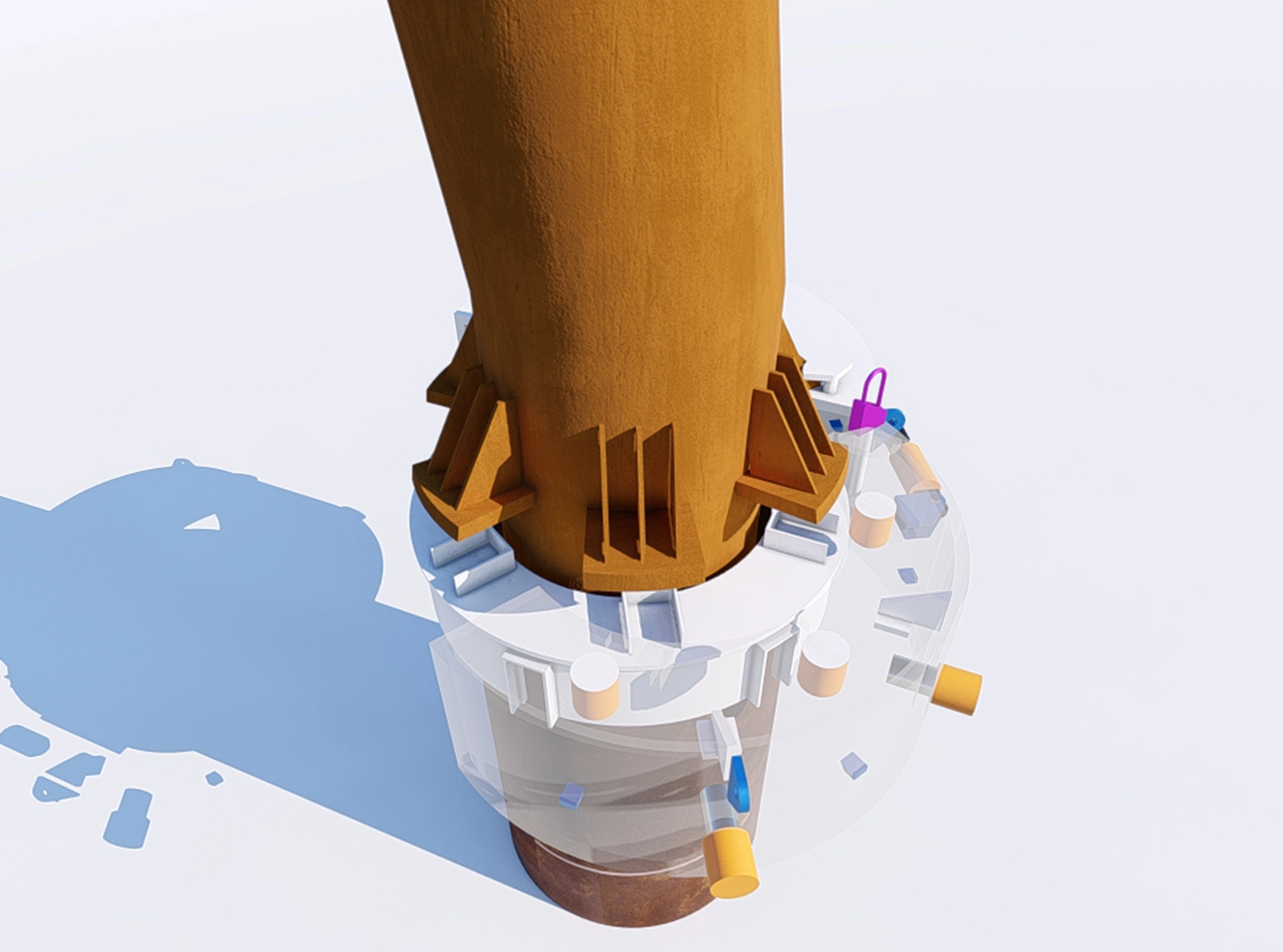

Innovation – Jacket Pile Gripper

A more sustainable and cost-effective approach for fixation during grout curing

The jacket foundation is becoming more popular as an offshore turbine foundation. Installing these jackets requires a lot of precision and binds contractors to strict installation tolerances. That is why we at TWD have introduced the innovative retrievable jacket pile gripper. It can easily be retrieved and reused for future jacket installations.

A jacket installation consists of multiple phases. First, pre-piles are driven into the seabed. Once the pre-piles are in place, the jacket piles are positioned into the pre-piles. Finally, the voids between the pre-piles and jacket piles are filled up with grout to secure the jacket to the pre-piles. When the grout is curing, the relative motions between the jacket leg and pin pile must be maintained within strict limits. Our retrievable jacket pile gripper makes this process efficient and cost-effective thanks to its reusability.

Project highlights

- Ensures limited relative motions between jacket leg and pin pile

- Retrievable system

- Hydraulic components not critical for jacket fabrication; reducing costs of jacket installation campaigns

- No unnecessary material left on the seabed

- Limited welding to jacket

- Remotely operated

As the global wind energy sector expands, a shortage of vessels for handling bigger monopiles is foreseen. Simply scaling up isn’t enough. Download our Whitepaper to explore how TWD tackles supply chain bottlenecks with innovative installation methods, or get our Offshore Wind Track Record to see how we have helped industry leaders succeed in their installations.