News

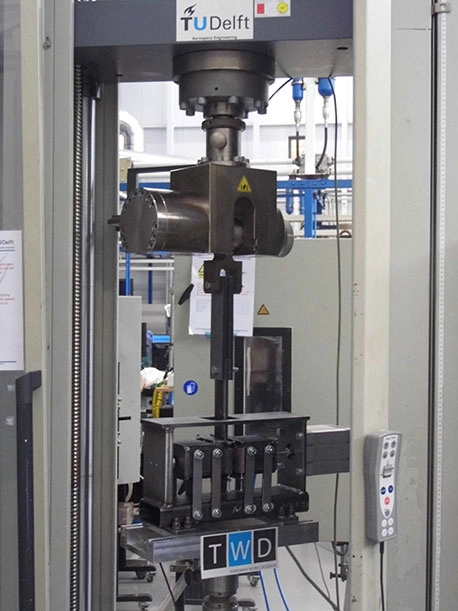

Friction Test Setup

- 24 May 2017

- News

Seafastening designs relying on friction result in simple and effective support structures securing heavy cargo to the deck of a transport vessel.

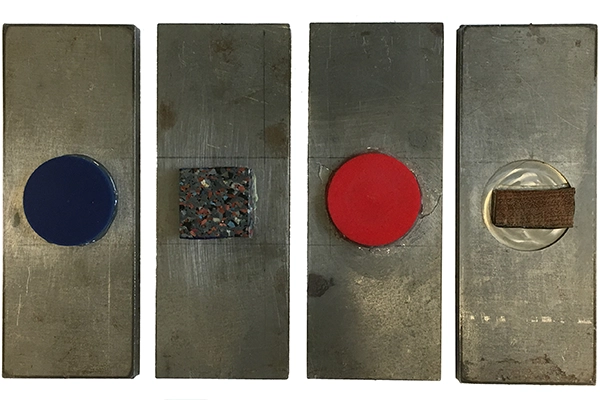

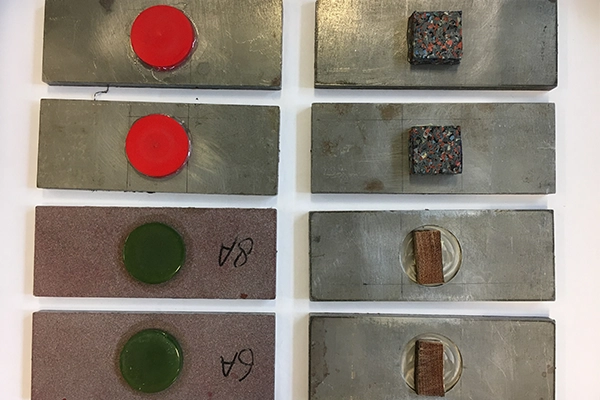

Especially where WTG foundations are transported offshore, large amounts of seafastening steel (and money) can be saved if sufficient friction can be assured to prevent WTG foundations from moving. Offshore design codes prescribe friction coefficients but don’t take into account unique material combinations, loading, and environmental conditions. Therefore, these coefficients are conservatively assumed and result in a high level of uncertainty.

For measuring the friction coefficient which is applicable to a specific transport, TWD developed a friction test set-up in cooperation with TU Delft. By simulating the actual transport situation, optimizations to both the seafastening design and the allowable transit conditions can be achieved, resulting in significant weight and cost reductions for the transporting contractor.

The friction tests are cost-effective and give results quickly. With the ready-to-use test facilities, all uncertainties related to the friction coefficient can be eliminated and the optimal seafastening design can achieved, giving confidence to all stakeholders.

If you want to optimize your operations, please feel free to contact us for pricing information and technical inquiries.

Share this article on